YoshiMoshi

- 233

- 10

Does anyone on here have a 3D printer for metal? I'm looking to get a custom made socket wrench fabricated for 10 mm bolts or nuts. I'm looking for one that is extremely low profile. I don't care about the drive style (1/4", 1/2", 3/4", 1", external hex etc).

The smallest mass produced one I could find was 3/8" drive at 17.3 mm in overall length

https://shop.snapon.com/product/Low...ic-10-mm-Flank-Drive-Low-Profile-Socket/RFM10

This however would require 3/8 drive ratchet or lever adding to the overall length above the nut or bolt.

The used to make a smaller on that was a twist socket that would damage a good nut or bolt

https://shop.snapon.com/product/Ext...nal-Drive-Hex-Head-Slim-Twist-Socket/110STSY2

That is only 9.5 mm in overall length, and it's a 5/8" external hex driven. Meaning I can just use a box end wrench that is 5/8", so the overall length above the bolt or nut would be 9.5 mm. I called them and asked them if they had something similar to this that wasn't a twist socket, and they said they don't.

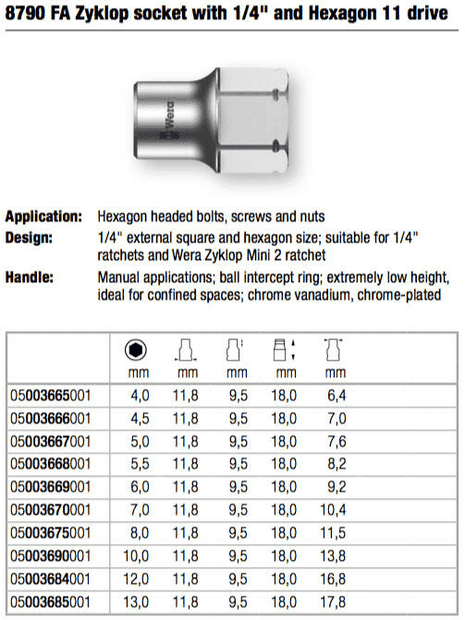

I found a Wera socket whose overall length is 18 mm.

It is driven by a 1/4" external hex. So I could use a box end wrench to rotate it. This seems to be the smallest mass produced profile tool I could find for a non-damaged 10 mm bolt or nut, requiring only 18 mm above the nut or bolt.

This won't work for my application. I'm trying to remove a bolt on a transmission pan that is right up against the subframe with very little clearance. 18 mm is to large. I can't find something smaller. Can someone with a 3D printer make a smaller 10 mm socket? Not sure how much this would cost. Or if someone has gone to a professional company that manufacturers custom tools, how much would something like this cost? This is merely out of convenience for me. I could always go through the hassle of undoing one of the mounts and jack it up. Much faster if I can just get a slimer profile socket. So if fabrication of a smaller socket will cost way to much money, then it's not worth it to me.

Please and thanks.

The smallest mass produced one I could find was 3/8" drive at 17.3 mm in overall length

https://shop.snapon.com/product/Low...ic-10-mm-Flank-Drive-Low-Profile-Socket/RFM10

This however would require 3/8 drive ratchet or lever adding to the overall length above the nut or bolt.

The used to make a smaller on that was a twist socket that would damage a good nut or bolt

https://shop.snapon.com/product/Ext...nal-Drive-Hex-Head-Slim-Twist-Socket/110STSY2

That is only 9.5 mm in overall length, and it's a 5/8" external hex driven. Meaning I can just use a box end wrench that is 5/8", so the overall length above the bolt or nut would be 9.5 mm. I called them and asked them if they had something similar to this that wasn't a twist socket, and they said they don't.

I found a Wera socket whose overall length is 18 mm.

It is driven by a 1/4" external hex. So I could use a box end wrench to rotate it. This seems to be the smallest mass produced profile tool I could find for a non-damaged 10 mm bolt or nut, requiring only 18 mm above the nut or bolt.

This won't work for my application. I'm trying to remove a bolt on a transmission pan that is right up against the subframe with very little clearance. 18 mm is to large. I can't find something smaller. Can someone with a 3D printer make a smaller 10 mm socket? Not sure how much this would cost. Or if someone has gone to a professional company that manufacturers custom tools, how much would something like this cost? This is merely out of convenience for me. I could always go through the hassle of undoing one of the mounts and jack it up. Much faster if I can just get a slimer profile socket. So if fabrication of a smaller socket will cost way to much money, then it's not worth it to me.

Please and thanks.