marellasunny

- 245

- 3

Alternatives to varistors as overload protection at DC motor

DC Motor here implies 12V linear actuator w/DC Motor that consumes 2.8A under loading condition. Pretty costly equipment.

I'm using a L298N motor driver connected in parallel to run the linear actuator. The motor driver is run by a 12V 10Ah lead acid battery. An electrical engineer advised me to use varistors 'MOVs' instead of 10A blade fuses for overload protection at my linear actuator. He specified that I select a varistor rated at 1.5x12V=18V rms and 1000A surge. I've been able to source only 130V rated Varistors in my locality/country. Is there any other alternative cheap way to ensure surge protection of my costly linear actuator? Are the fuses engh?

From what I've read varistors start to conduct current only above the DC rated voltage.

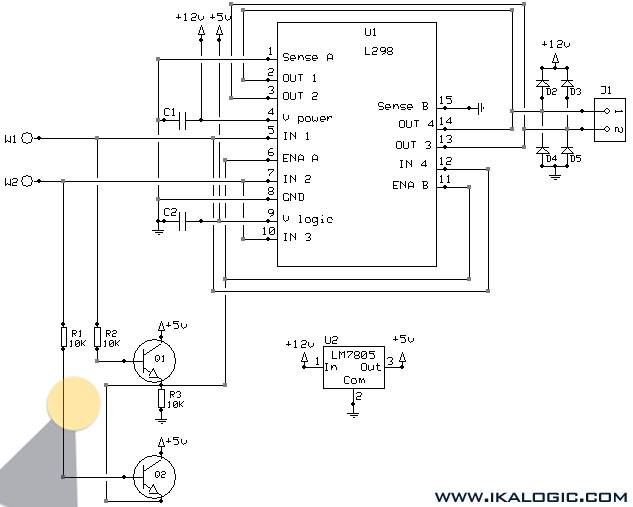

L298N connected in parallel:

Varistor working:

10A blade fuse:

http://s1097.photobucket.com/user/wlwltd/media/10_AMP_BLADE_FUSE_STANDARD_2.jpg.html?t=1324466963

DC Motor here implies 12V linear actuator w/DC Motor that consumes 2.8A under loading condition. Pretty costly equipment.

I'm using a L298N motor driver connected in parallel to run the linear actuator. The motor driver is run by a 12V 10Ah lead acid battery. An electrical engineer advised me to use varistors 'MOVs' instead of 10A blade fuses for overload protection at my linear actuator. He specified that I select a varistor rated at 1.5x12V=18V rms and 1000A surge. I've been able to source only 130V rated Varistors in my locality/country. Is there any other alternative cheap way to ensure surge protection of my costly linear actuator? Are the fuses engh?

From what I've read varistors start to conduct current only above the DC rated voltage.

L298N connected in parallel:

Varistor working:

10A blade fuse:

http://s1097.photobucket.com/user/wlwltd/media/10_AMP_BLADE_FUSE_STANDARD_2.jpg.html?t=1324466963