Discussion Overview

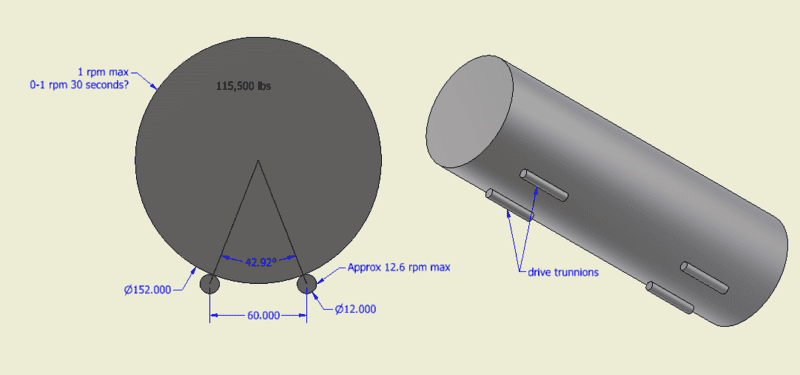

The discussion revolves around calculating the torque required to rotate large drums in a paint booth, focusing on the mechanics involved in the design of a fixture that utilizes drive trunnions. Participants explore the theoretical and practical aspects of torque calculation, including factors such as mass distribution, moment of inertia, and frictional forces.

Discussion Character

- Technical explanation

- Conceptual clarification

- Debate/contested

- Mathematical reasoning

Main Points Raised

- Some participants note that the torque required to accelerate the drum depends on its moment of inertia, which is influenced by the mass distribution of the drum and its contents.

- There is a question about how to calculate the moment of inertia for a drum that is semi-filled with a viscous liquid, such as paint, and how this affects the torque needed.

- One participant mentions that the trunnion bearings will be large PB Tapered Roller Bearings, which may influence the frictional forces at play.

- Concerns are raised about the potential for slip between the trunnion and the drum, although some participants believe this may not be an issue due to the slow speeds involved.

- There is a discussion about the design of the rollers and their placement, with questions about how they might prevent damage to the painted surface of the drum.

- One participant emphasizes the importance of minimizing rolling friction to accurately determine the required drive torque.

- Another participant expresses confidence in the drum design and the adequacy of the tire area to prevent deformation under load.

- There is a suggestion to verify the safety of the design to prevent the drum from escaping during operation.

- Some participants discuss the implications of using a variable frequency drive (VFD) for the motors, especially considering the weight of the drum.

- Concerns are raised about the material of the "tire" and its potential deformation under load, which could affect the energy requirements for rotation.

Areas of Agreement / Disagreement

Participants express a mix of agreement and differing views on various aspects of the torque calculation, including the effects of mass distribution, friction, and design considerations. The discussion remains unresolved with multiple competing views on the best approach to calculating the required torque.

Contextual Notes

Participants mention various assumptions, such as the mass distribution being even when the drum is empty and the potential effects of viscous liquid on torque calculations. There are also unresolved questions regarding the specific design and material properties of the components involved.