JoshDeM

- 1

- 1

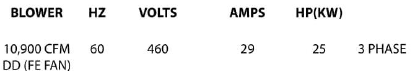

I've been given some specifications by a company for an exhaust fan that I am looking at purchasing for my company. They tell me it is 10,900 cfm. Then given some specs on the electrical requirements. I am wondering with the information given could I check their given flow rate?

I imagine that I will need to make a few assumptions along the way. I want to make sure they aren't out to lunch.

Below are the specs

I imagine that I will need to make a few assumptions along the way. I want to make sure they aren't out to lunch.

Below are the specs