- #1

Gbl911

- 17

- 0

I am doing a experiment with model rockets to see if a added compression nozzle on a model rocket would make the engine perform better.

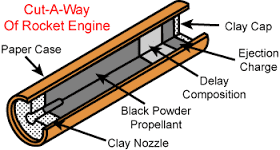

As you can see in this picture there is a small clay nozzle immediate to the propellant. This is the same place that you put the igniter.

As you can see in this picture there is a small clay nozzle immediate to the propellant. This is the same place that you put the igniter.

My experiment is going to test to see if adding a additional exterior compression nozzle will more improve the performance.

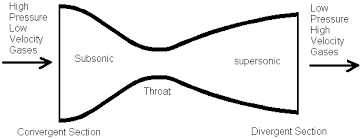

This is along the lines of what I am planning to make. I would like to get an opinion if this would actually make a difference.

This is along the lines of what I am planning to make. I would like to get an opinion if this would actually make a difference.

Thanks

My experiment is going to test to see if adding a additional exterior compression nozzle will more improve the performance.

Thanks