Discussion Overview

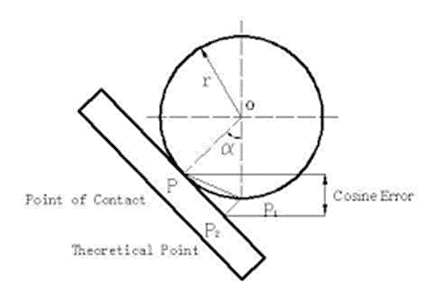

The discussion revolves around the concept of cosine error in relation to a 5 mm ball tip stylus measuring a surface at a 7.5° angle. Participants explore the implications of cosine error on measurement accuracy, particularly in the context of varying surface geometries compared to CAD nominal values.

Discussion Character

- Technical explanation, Mathematical reasoning, Debate/contested

Main Points Raised

- Some participants assert that cosine error is a vector and depends on the angle between the probe and the normal vector, suggesting that as this angle increases, the error also increases.

- One participant presents a formula for cosine error, expressed as $$ \epsilon = r \left[ 1-\cos \alpha + \sin \alpha \cos \alpha \tan \frac{\alpha}{2} \right]$$, indicating a mathematical approach to quantify the error.

- Another participant proposes alternative formulations for cosine error, including $$ \epsilon = r \left( 1- \cos \alpha \right) \left( 1 + \cos \alpha \right)$$ and $$ \epsilon = r \sin^2 \alpha$$, suggesting these may be cleaner or more computationally efficient.

- One participant calculates the cosine error using the last formula, arriving at an approximate value of 0.085 mm for the given angle.

- A later reply emphasizes the significance of even small errors, noting that an error of 0.0033" is considerable when checking high precision parts.

Areas of Agreement / Disagreement

Participants express differing views on the best mathematical representation of cosine error, with no consensus on a single formula. While some agree on the implications of cosine error, the discussion remains unresolved regarding the optimal approach to quantify it.

Contextual Notes

Participants reference various mathematical formulations without resolving potential discrepancies in their equivalence or applicability. The discussion does not clarify the assumptions underlying the calculations or the specific conditions under which the formulas are valid.