timotola

- 6

- 2

Hi,

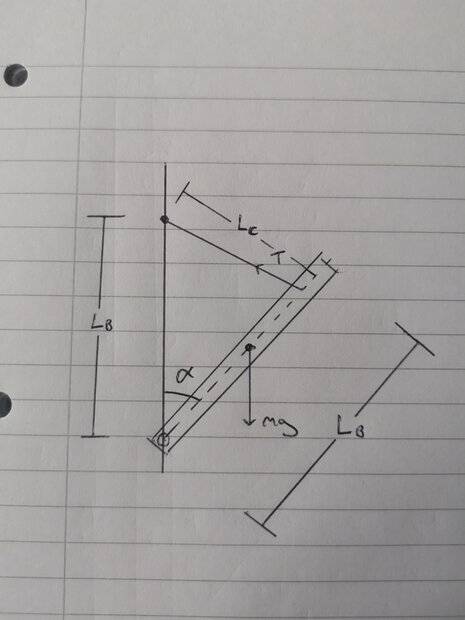

I'm currently looking into the forces exerted on a cable if the cable was to go from slack to taut due to a falling object that is pivoted about a lower hinge - such as a drawbridge but instead of slowly lowering, there is slack in the cable causing the bridge to freely rotate about the lower hinge before arresting by the cable once the slack is taken up.

I'll attach a rough sketch to visualise what I'm thinking.

I'm assuming that the bridge starts at angular velocity = 0 in the upright position before finishing as drawn. I'm also understanding that the cable must undergo some extension to calculate the tension based on the rotational kinetic energy, hence, there should be a spring constant type property for the cable?

Any guidance on this one will be much appreciated, thanks.

I'm currently looking into the forces exerted on a cable if the cable was to go from slack to taut due to a falling object that is pivoted about a lower hinge - such as a drawbridge but instead of slowly lowering, there is slack in the cable causing the bridge to freely rotate about the lower hinge before arresting by the cable once the slack is taken up.

I'll attach a rough sketch to visualise what I'm thinking.

I'm assuming that the bridge starts at angular velocity = 0 in the upright position before finishing as drawn. I'm also understanding that the cable must undergo some extension to calculate the tension based on the rotational kinetic energy, hence, there should be a spring constant type property for the cable?

Any guidance on this one will be much appreciated, thanks.