Powderbullet

- 3

- 1

- TL;DR

- Using a winch cable to rotate a drum

I farm and have built water control devices for my rice operation that use a cable and drum setup. The moving part is a 24"water tight rotary union that we rotate with a cable that originates in a dual spool winch above the center line of rotation for the drum. The winch cables secure to the bottom of the drum by wrapping each side. So it is like a continuous loop back to the winch but the cables anchor beneath to the drum. My question has to do with angle of pull and lateral loads.

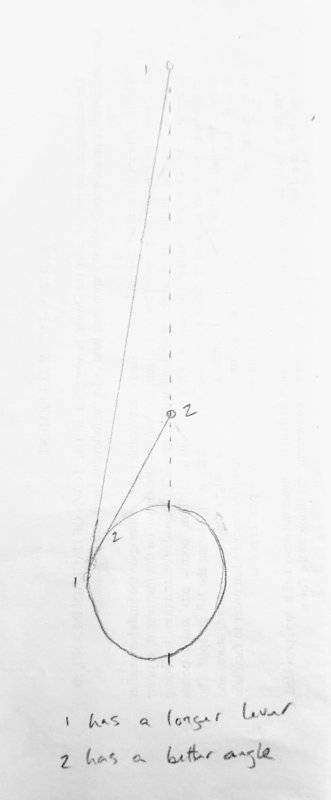

In the attached drawing you can see that example 1 (which only shows one side of the dual spool setup) puts the winch high above the drum. The point of pull is near the outside edge of the drum at the 9:00 position which means the lever is the greatest it can be and the lateral loads on the winch pedestal are a greater concern. Example 2 puts the winch lower, which moves the point of pull closer to center line and thereby reduces leverage but it also reduces the lateral load issue on the pedestal by allowing it to be shorter and thereby less likely to bend to the load. Is the angle of pull a key component or are the only 2 issues leverage and lateral loads?

I am thinking of putting a cable guide straight down the pedestal leg from the winch, which would allow me to set the guide / point of pull height above the drum anywhere I wanted it regardless of the height of the actual winch. So I am trying optimize the placement of the guide / point of pull for a 24" drum. Thanks for any suggestions!

In the attached drawing you can see that example 1 (which only shows one side of the dual spool setup) puts the winch high above the drum. The point of pull is near the outside edge of the drum at the 9:00 position which means the lever is the greatest it can be and the lateral loads on the winch pedestal are a greater concern. Example 2 puts the winch lower, which moves the point of pull closer to center line and thereby reduces leverage but it also reduces the lateral load issue on the pedestal by allowing it to be shorter and thereby less likely to bend to the load. Is the angle of pull a key component or are the only 2 issues leverage and lateral loads?

I am thinking of putting a cable guide straight down the pedestal leg from the winch, which would allow me to set the guide / point of pull height above the drum anywhere I wanted it regardless of the height of the actual winch. So I am trying optimize the placement of the guide / point of pull for a 24" drum. Thanks for any suggestions!