Dreezy

- 2

- 0

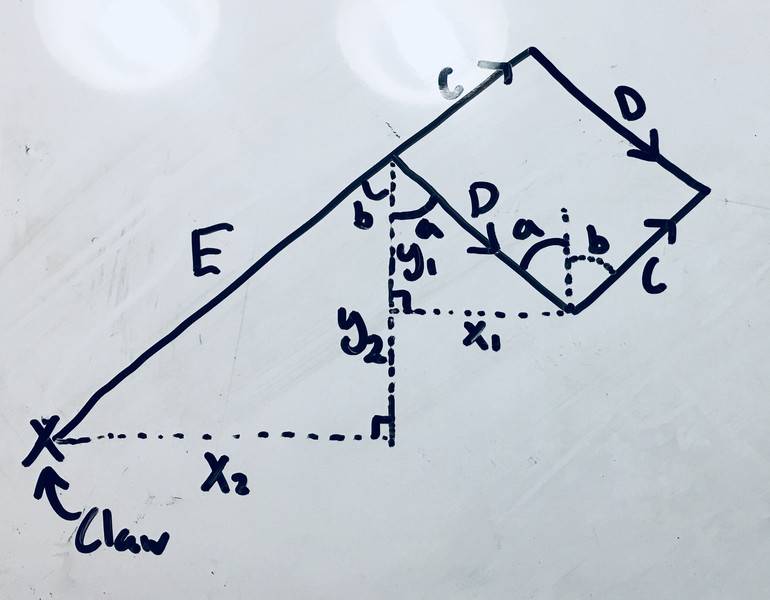

Hey guys, I would appreciate some help with the math behind creating a working coordinate system for a robotic arm. I am currently trying to determine what servo angles are necessary to align a robotic arm's claw to the given coordinates. Geometrically simplified, the robotic arm is a parallelogram with two servos at one vertex and one side extended further for the claw. Here is a diagram, pardon my drawing skills:

The sides marked D are parallel and equivalent, as are the sides marked C. E is of fixed length and is attached to C (in reality it is just the extension of the C piece). The servos at bottom vertex DC adjust angles a and b to move sides D and C from the vertical. The claw itself is at the end of E, and x refers to the horizontal distance and y the vertical distance from the origin of the two angles a and b (AKA where the servos are placed).

As for what I have tried, I have calculated the claw's coordinates to be X=D*sin(a)+E*sin(b) and Y=D*cos(a)-E*cos(b), but I am unable to solve the system of equations such that I can determine what to set angles a and b to move the claw to a given point. When using substitution, I only end up with an extremely convoluted equation that my calculator cannot parse, leading me to believe I am going down the wrong path. Any help would be much appreciated!

(Also would like to mention for full transparency that this was cross posted to the Math Stack Exchange to no avail)

The sides marked D are parallel and equivalent, as are the sides marked C. E is of fixed length and is attached to C (in reality it is just the extension of the C piece). The servos at bottom vertex DC adjust angles a and b to move sides D and C from the vertical. The claw itself is at the end of E, and x refers to the horizontal distance and y the vertical distance from the origin of the two angles a and b (AKA where the servos are placed).

As for what I have tried, I have calculated the claw's coordinates to be X=D*sin(a)+E*sin(b) and Y=D*cos(a)-E*cos(b), but I am unable to solve the system of equations such that I can determine what to set angles a and b to move the claw to a given point. When using substitution, I only end up with an extremely convoluted equation that my calculator cannot parse, leading me to believe I am going down the wrong path. Any help would be much appreciated!

(Also would like to mention for full transparency that this was cross posted to the Math Stack Exchange to no avail)