- #1

ENGBIO

- 19

- 1

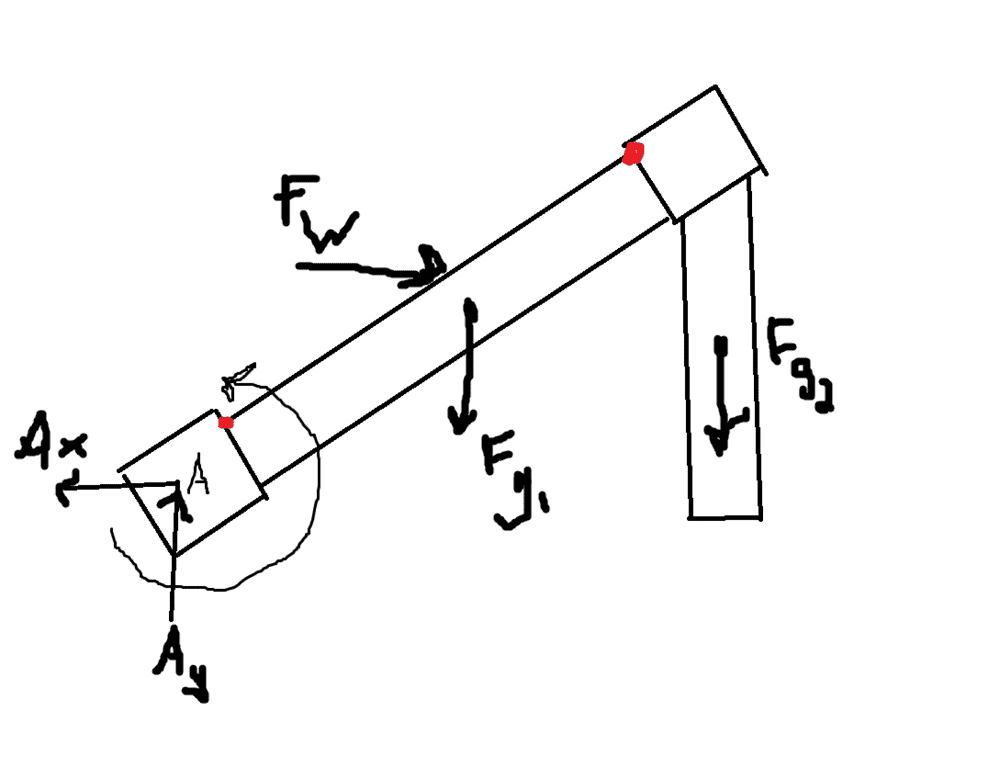

Hey everybody so I am a student and I am learning about failure analysis. So let's say I have a rigid body that is being kept in this position...there is a moment at A generated by a motor to keep the body in this position, working against the weight of the body itself and small wind force. There are bearing reactions at A. I know about making shear and bending diagrams but when it is angled like this how do I calculate if it will fail at these spots?