Ham94

- 1

- 0

- TL;DR

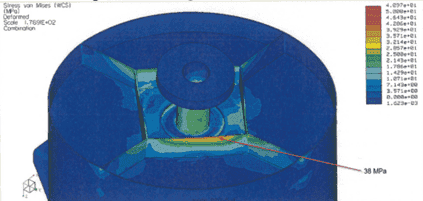

- How to calculate a complex construction for the maximum stress or stress in the stiffenerconstruction? there are forces and momentums in the x,y,z, direction. They work in the most worst direction. I don't know how to handle this subject.

A Construction is stiffened by a bottemplate with welded ribs. A flange welded to the inletpipe is bolted at the botomplate. I want to simulate the current situation. Therfore I need a handcalculation of the stresses in the ribs of the constuction. The forces and moments are working in the worst case direction.

fx=6kN

fy=6kN

fz=6kN

Mx=6kNm

My=6kNm

Mz=6kNm

underside

underside

Casingdiameter =900 mm

Casingthickness=5 mm

Botemplatethickness=5 mm

squareribs= 400*400

ribthickness=5 mm

height rib= 120 mm

length of ribs form square to circular casing= 4* 162 mm (angle from center 90=°, t=5 mm)

hole bottomplate= 250 mm

flangediamater= 350 mm

I don't know how to handle this situation. I want to calculate the maximum stresses in the ribs OR the stresses in a rib at one point.

Is there a possability to calculate without a inertia moment?

I have tried to calculatie the inertia moment of te ribs, but by second thought it is difficult because of the integrals and the positions of the ribs.

Maybe my thought is even harder than the solution.

fx=6kN

fy=6kN

fz=6kN

Mx=6kNm

My=6kNm

Mz=6kNm

Casingdiameter =900 mm

Casingthickness=5 mm

Botemplatethickness=5 mm

squareribs= 400*400

ribthickness=5 mm

height rib= 120 mm

length of ribs form square to circular casing= 4* 162 mm (angle from center 90=°, t=5 mm)

hole bottomplate= 250 mm

flangediamater= 350 mm

I don't know how to handle this situation. I want to calculate the maximum stresses in the ribs OR the stresses in a rib at one point.

Is there a possability to calculate without a inertia moment?

I have tried to calculatie the inertia moment of te ribs, but by second thought it is difficult because of the integrals and the positions of the ribs.

Maybe my thought is even harder than the solution.

Last edited: