Amaelle

- 309

- 54

- TL;DR

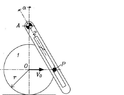

- I have an issue in making the small ball slide into the groove

Good day All!

I have a problem , I could do almost all the mechanism, my problem is how to make slide the little ball into the groove. whenever i run the program i got the follwing error message

['rotating_groove_cylinder_good_trial']: The following errors were found in the model rotating_groove_cylinder_good_trial.

Caused by:

['rotating_groove_cylinder_good_trial/Solver Configuration']: *** Model not assembled: position violation *** Resolve this issue in order to simulate the model.

the wheel rotates around a fixed hinge.

I have joined the program file,

Many thanks in advance

I have a problem , I could do almost all the mechanism, my problem is how to make slide the little ball into the groove. whenever i run the program i got the follwing error message

['rotating_groove_cylinder_good_trial']: The following errors were found in the model rotating_groove_cylinder_good_trial.

Caused by:

['rotating_groove_cylinder_good_trial/Solver Configuration']: *** Model not assembled: position violation *** Resolve this issue in order to simulate the model.

the wheel rotates around a fixed hinge.

I have joined the program file,

Many thanks in advance

Attachments

Last edited: