ConnorM

- 77

- 1

Problem

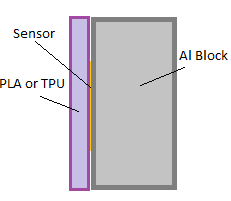

I am designing a force sensing system with piezoelectric force sensors to determine the impact force on an object during a collision. The sensor will be placed between an aluminum block and either a TPU or PLA 3D printed "cover". The cover will be 5cm thick.

Attempt

My goal is to determine how much impact energy will be absorbed by the cover material and how much will be transmitted to the sensors sensing surface (5cm*5cm). Once I know this I think that I should be able to take the value measured by the force sensor and sub it into some function to relate it to the impact force on the outer surface of the cover material.

If I have the material properties of PLA and TPU (Young's modulus, density, etc), the dimensions of the cover, the impact force area, and the force value measured by the sensor, is it possible to come up with some equation?

Maybe this is too complex and the force on the outside of the material will almost 100% be transmitted to the sensor.

Could someone let me know what they think and what steps I should take going forward?

I am designing a force sensing system with piezoelectric force sensors to determine the impact force on an object during a collision. The sensor will be placed between an aluminum block and either a TPU or PLA 3D printed "cover". The cover will be 5cm thick.

Attempt

My goal is to determine how much impact energy will be absorbed by the cover material and how much will be transmitted to the sensors sensing surface (5cm*5cm). Once I know this I think that I should be able to take the value measured by the force sensor and sub it into some function to relate it to the impact force on the outer surface of the cover material.

If I have the material properties of PLA and TPU (Young's modulus, density, etc), the dimensions of the cover, the impact force area, and the force value measured by the sensor, is it possible to come up with some equation?

Maybe this is too complex and the force on the outside of the material will almost 100% be transmitted to the sensor.

Could someone let me know what they think and what steps I should take going forward?