DaveC426913

Gold Member

2025 Award

- 24,251

- 8,368

This seems like a naive question, yet I keep pondering it while looking at the safety lines on my boat.

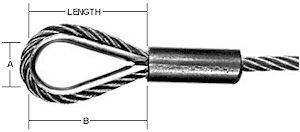

They're braided cable with thimbles:

The length is not adjustable, so I need to finish them with strong line (one zillion pounds breaking force) that can be adjusted to make the safety line taut.

My question is this:

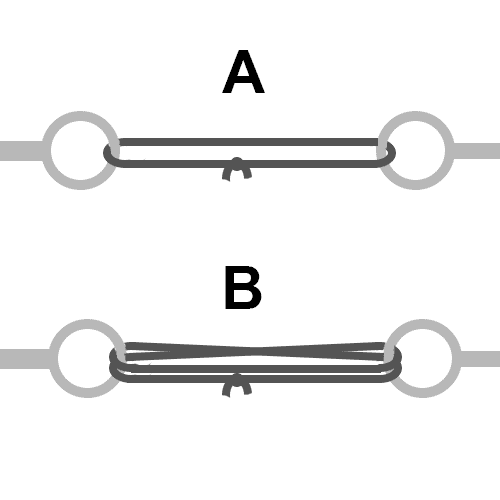

Is a double-loop line (B) functionally stronger than a single loop (A)?

It is elementary that, if the line breaks in either A or B (say, due to rubbing wear), it doesn't matter how many loops I have, it will come apart.

But does the double loop distribute the load, so that it will hold more weight?

They're braided cable with thimbles:

The length is not adjustable, so I need to finish them with strong line (one zillion pounds breaking force) that can be adjusted to make the safety line taut.

My question is this:

Is a double-loop line (B) functionally stronger than a single loop (A)?

It is elementary that, if the line breaks in either A or B (say, due to rubbing wear), it doesn't matter how many loops I have, it will come apart.

But does the double loop distribute the load, so that it will hold more weight?