Discussion Overview

The discussion revolves around the potential for thermal expansion fatigue in aluminum alloy motorcycle frames, particularly considering daily temperature variations and their effects on microstructural integrity. Participants explore the implications of thermal cycling on material properties, fatigue limits, and the longevity of motorcycle frames under varying conditions.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

Main Points Raised

- Some participants question whether daily temperature variations can induce thermal fatigue in aluminum alloy frames, considering the extent of microstructural changes that may occur.

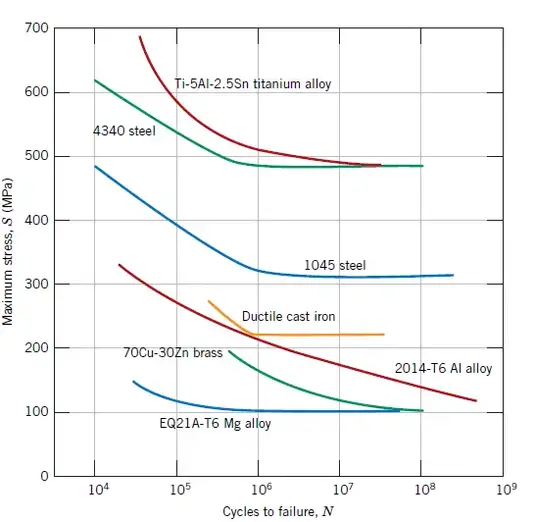

- One participant notes that aluminum alloys do not have a fatigue limit, suggesting that any work cycle could result in microstructural changes.

- Another participant presents a graph indicating that under certain thermal stress conditions, aluminum parts could last significantly long, but stresses from daily temperature changes remain uncertain.

- Some participants express skepticism about the amount of stress induced by daily temperature changes, comparing it to the more complex stress scenarios in commercial airplane fuselages.

- There is a discussion about the industrial practice of heating metal parts to relieve internal stresses, which may apply to motorcycle frames as well.

- One participant raises a question about the existence of a minimum load limit for fatigue in aluminum, suggesting that even minimal loads could theoretically lead to microstructural changes over time.

- Concerns are raised about the potential for internal dislocations due to thermal expansion, especially at bolted connections in the frame.

Areas of Agreement / Disagreement

Participants do not reach a consensus on whether thermal expansion fatigue is a significant concern for aluminum alloy motorcycle frames. Multiple competing views exist regarding the effects of temperature changes on material integrity and the nature of fatigue in aluminum.

Contextual Notes

Participants acknowledge that aluminum frames are typically heat treated to enhance strength and relieve stress, but the implications of thermal cycling on microstructural integrity remain unresolved. The discussion highlights the complexity of fatigue behavior in aluminum compared to other materials like steel.