- #1

prefetch

- 23

- 0

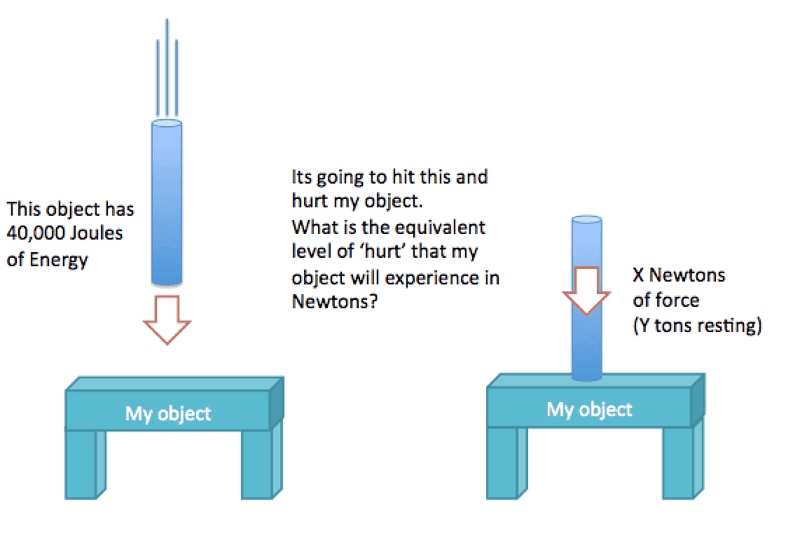

hi guys - this is not a homework problem. I'm way too old to be in school - I'm actually trying to solve a "real world" problem and I'm just a dumb computer scientist pretending to be a mechanical engineer. I'm working on designing a frame for a vehicle and I'm using a couple of different software packages. one of them tells about joules of energy that my frame could get hit by, and the other tells me how resistant my frame by simulating Newtons of force on it.

i'd like to understand the equivalence of these two things, so i can sync up my designed between the two software systems.

here's the picture of my question - any help would be very much appreciated.

i'd like to understand the equivalence of these two things, so i can sync up my designed between the two software systems.

here's the picture of my question - any help would be very much appreciated.