FEAnalyst

- 348

- 149

- TL;DR

- How to calculate the deflection of a leaf spring?

Hi,

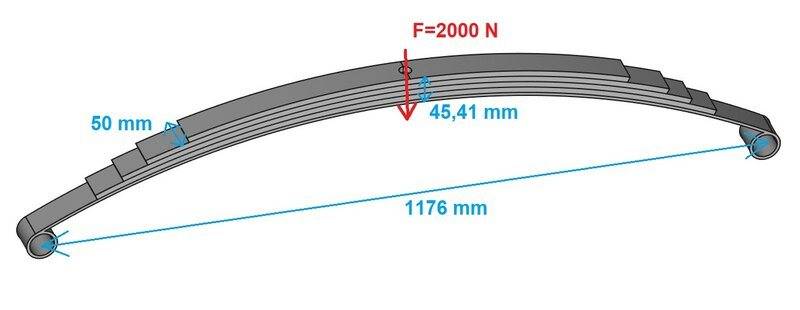

I'm trying to calculate the deflection of a leaf spring. I've found several formulas but the one I'm currently using looks like this: $$f=k \frac{F L^{3}}{6EI}$$ where: ##k## - coefficient depending on the way leaves change their shape in the width direction (in my case it's ##1## because leaves are not tapered if you look at them from below), ##F## - force, ##L## - length of the spring (between the centers of both eyes), ##E## - Young's modulus, ##I## - section moment of inertia. I calculated ##I## using a standard formula for rectangular section: $$I=\frac{bh^{3}}{12}$$ where: ##b## - width of the spring, ##h## - height of the whole section (sum of all layers' heights). My leaf spring is curved (initially bent) but I think that this formula should account for that. I also assume that a small mounting hole in the middle where a force is applied doesn't influence the calculations too much.

Anyway, here's what I get for the data included in the picture above: $$f=\frac{2000 \cdot 1176^{3}}{6 \cdot 210000 \cdot \frac{50 \cdot 45,41^{3}}{12}}=6,62 \ mm$$ According to finite element analysis, the deflection in the middle of the spring should be around ##0,079 \ mm##... I checked all the inputs in both analytical and numerical calculation and I couldn't find any error. Do you know what can be wrong here ? I must have missed something or the formula is incorrect (I've found it in a Polish book about the design of cars).

I'm trying to calculate the deflection of a leaf spring. I've found several formulas but the one I'm currently using looks like this: $$f=k \frac{F L^{3}}{6EI}$$ where: ##k## - coefficient depending on the way leaves change their shape in the width direction (in my case it's ##1## because leaves are not tapered if you look at them from below), ##F## - force, ##L## - length of the spring (between the centers of both eyes), ##E## - Young's modulus, ##I## - section moment of inertia. I calculated ##I## using a standard formula for rectangular section: $$I=\frac{bh^{3}}{12}$$ where: ##b## - width of the spring, ##h## - height of the whole section (sum of all layers' heights). My leaf spring is curved (initially bent) but I think that this formula should account for that. I also assume that a small mounting hole in the middle where a force is applied doesn't influence the calculations too much.

Anyway, here's what I get for the data included in the picture above: $$f=\frac{2000 \cdot 1176^{3}}{6 \cdot 210000 \cdot \frac{50 \cdot 45,41^{3}}{12}}=6,62 \ mm$$ According to finite element analysis, the deflection in the middle of the spring should be around ##0,079 \ mm##... I checked all the inputs in both analytical and numerical calculation and I couldn't find any error. Do you know what can be wrong here ? I must have missed something or the formula is incorrect (I've found it in a Polish book about the design of cars).