Discussion Overview

The discussion revolves around the feasibility of using a garage door opener to lift a 40 lb load, specifically a TV, into an attic space. Participants explore various mechanical designs, including the use of sprockets, pulleys, counterweights, and linear actuators, while addressing the limitations and potential issues of each approach.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

- Conceptual clarification

Main Points Raised

- One participant suggests modifying the sprocket size on the garage door opener to increase lifting capacity, while another warns about the limitations of the existing bearing and the potential for reduced lifespan.

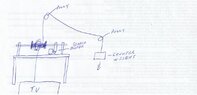

- There is a proposal to use a pulley system to reduce the load on the opener, allowing it to lift 40 lbs by only needing to pull 20 lbs.

- A counterweight system is discussed as a means to alleviate the load on the garage door opener, with suggestions for both external and internal configurations.

- Concerns are raised about the travel limitations of the garage door opener and the number of turns it can make.

- Some participants express a preference for using a linear actuator instead of a garage door opener, citing ease of control and integration with smart technology.

- Noise generated by the garage door opener is mentioned as a potential drawback, with suggestions for remote mounting to mitigate this issue.

- Alternative mechanisms, such as powered loft-access ladders and cantilever systems, are proposed for lifting the TV.

Areas of Agreement / Disagreement

Participants do not reach a consensus on the best approach to lift the TV. Multiple competing views remain regarding the use of a garage door opener versus other mechanisms, as well as the design of counterweights and the implications of noise and travel limitations.

Contextual Notes

Participants express uncertainty about the mechanical limits of the garage door opener, the effectiveness of various proposed designs, and the potential noise issues associated with using a garage door opener for this application.