SUMMARY

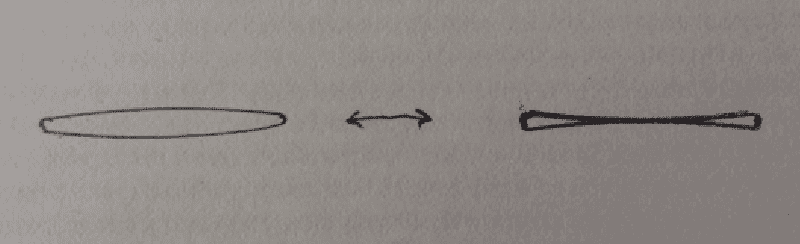

The discussion centers on finding a sealing solution for a thin oscillating opening measuring approximately 15mm x 2mm, subjected to low amplitude oscillations of +/- 1mm at frequencies between 100 Hz and 1000 Hz. The fluid involved is air, with an estimated pressure of around 2 kPa. Participants suggest using a thick, large diameter O-ring to effectively seal the opening while accommodating the oscillation without adversely affecting performance. The geometry of the components needing sealing is crucial for determining the appropriate sealing method.

PREREQUISITES

- Understanding of mechanical sealing concepts, specifically O-rings.

- Knowledge of oscillation dynamics in mechanical systems.

- Familiarity with pressure measurements in pneumatic systems.

- Basic principles of fluid dynamics, particularly in relation to air flow.

NEXT STEPS

- Research the design and application of O-rings in dynamic sealing environments.

- Investigate the effects of oscillation frequency on sealing performance.

- Explore custom valve design principles for pneumatic applications.

- Study the impact of pressure differentials on sealing materials and methods.

USEFUL FOR

Mechanical engineers, product designers, and anyone involved in the design of pneumatic systems requiring precise sealing solutions for oscillating components.