person123

- 326

- 52

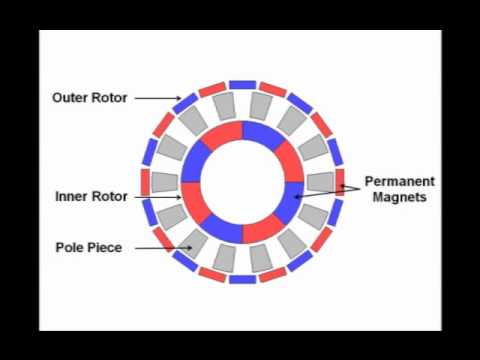

This thread is an attempt to better understand the pseudo direct drive, or PDD, gear. What I do know is it's made up of a set of magnets which can serve the function of a reducer- a basic diagram of it as well as a video can be seen below. In this mechanism, the inner rotor is the input while the pole pieces is the output. The outer rotor is said to usually remain stationary. Without any physical contact, the power is transmitted from the inner rotor to the pole pieces.

Would it, however, be possible for both rotors to become the inputs simultaneously? If, for example, the two rotors are going in different directions and with different speeds, would the pole pieces rotate based on both of the rotors, or would it instead fail to function? I couldn't find the answer to this question in any videos, and I would be interested in the opinion of this forum.

Would it, however, be possible for both rotors to become the inputs simultaneously? If, for example, the two rotors are going in different directions and with different speeds, would the pole pieces rotate based on both of the rotors, or would it instead fail to function? I couldn't find the answer to this question in any videos, and I would be interested in the opinion of this forum.

Last edited: