jeremyjong

- 1

- 0

Hi there. I have a project I am working on now which is kind of like a bicycle which uses powder clutches.

The main goal is to make the whole thing compact by reducing the use of shafts.

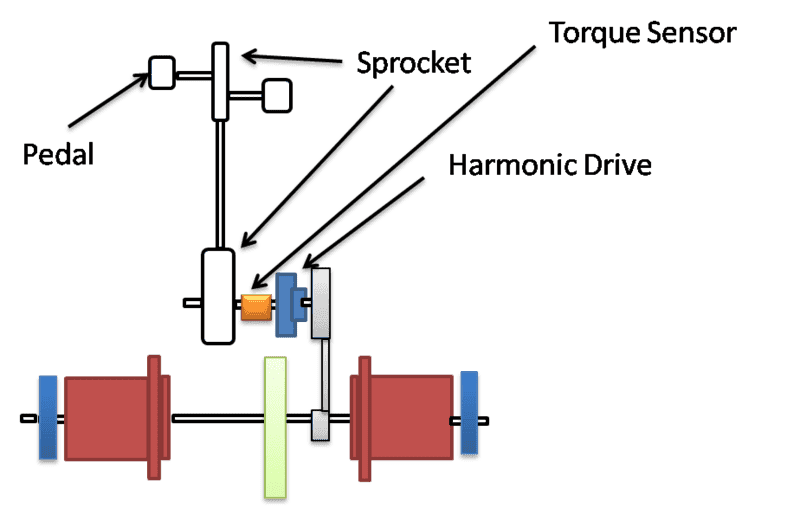

My initial idea of part of the mechanism is in the picture below.

I was planning on putting the torque sensor, harmonic drive and pulley all on the same shaft.

But with the sizes of the harmonic and all (coupling and the others) , I ended up with this.

&...Back to the question.

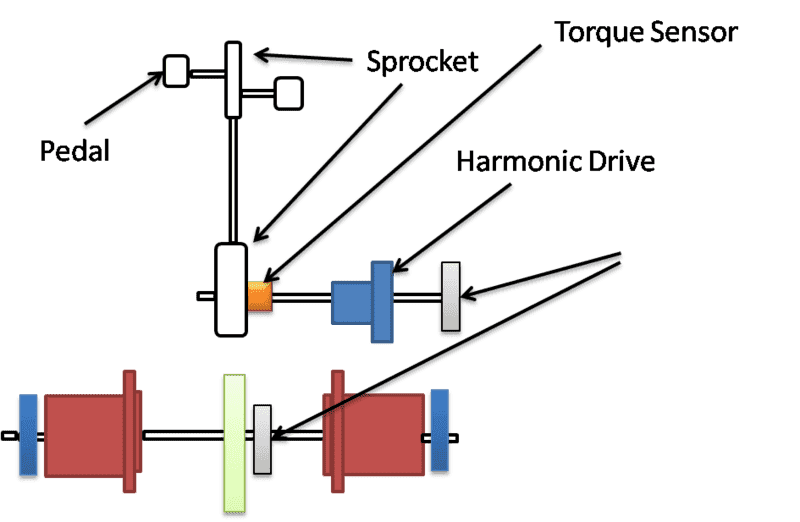

Is it possible to connect the pulley on the input shaft(that ended up on the far right)

to the output shaft pulley(that is statically situated in the middle?)

I know I could add another shaft and use another pulley to connect the two, but I prefer not to

as that would end up with a another shaft and making the size larger.

Is there any possible ways that might make this possible?

Thank you.

The main goal is to make the whole thing compact by reducing the use of shafts.

My initial idea of part of the mechanism is in the picture below.

I was planning on putting the torque sensor, harmonic drive and pulley all on the same shaft.

But with the sizes of the harmonic and all (coupling and the others) , I ended up with this.

&...Back to the question.

Is it possible to connect the pulley on the input shaft(that ended up on the far right)

to the output shaft pulley(that is statically situated in the middle?)

I know I could add another shaft and use another pulley to connect the two, but I prefer not to

as that would end up with a another shaft and making the size larger.

Is there any possible ways that might make this possible?

Thank you.