- #1

Arun John

- 1

- 0

Hi I am trying to make a CAD model of something like the scoop sampler shown below.

http://www.rolls-royce.com/~/media/...tomers/nuclear/scoop-sampling-tcm92-50918.pdf

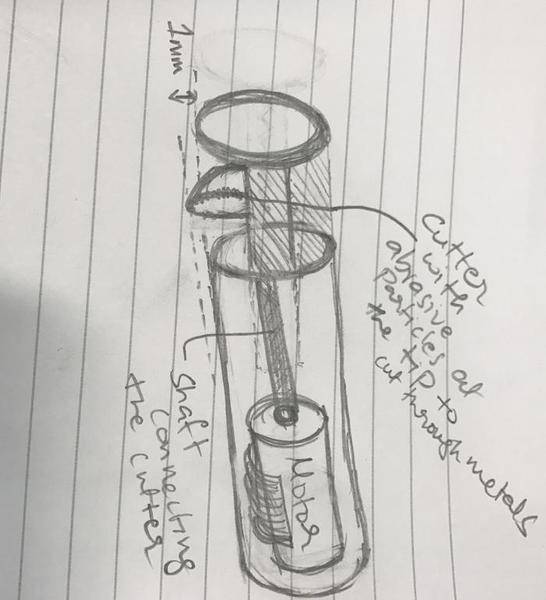

This is for a university coursework that requires design of bespoke machines. I am trying to design a machine that can literally scoop out a 1 mm thick sample from any aerospace component. My intention is to use a motor to rotate the shaft which is connected to the cutter (with abrasive particles to cut through metal).

See this would initiate the cutting and only cut at the controlled depth (based on the dimension of the cutter) but how can I possibly make the cutter to eventually go up? (lets say after 35 - 40mm length I want the cutter to make a vertical movement so that it scoops out). To clarify I want the final metal scoop to be roughly 40mm long, 20mm wide and max thickness of 1mm. So once it reaches around 35mm how can I make it go up vertically while the shaft and cutter is rotating in the horizontal axis?

Finally what if I don't have a flat surface. Imagine if I have a concave surface. I have some ideas but I can't seem to get through these initial problems.

http://www.rolls-royce.com/~/media/...tomers/nuclear/scoop-sampling-tcm92-50918.pdf

This is for a university coursework that requires design of bespoke machines. I am trying to design a machine that can literally scoop out a 1 mm thick sample from any aerospace component. My intention is to use a motor to rotate the shaft which is connected to the cutter (with abrasive particles to cut through metal).

See this would initiate the cutting and only cut at the controlled depth (based on the dimension of the cutter) but how can I possibly make the cutter to eventually go up? (lets say after 35 - 40mm length I want the cutter to make a vertical movement so that it scoops out). To clarify I want the final metal scoop to be roughly 40mm long, 20mm wide and max thickness of 1mm. So once it reaches around 35mm how can I make it go up vertically while the shaft and cutter is rotating in the horizontal axis?

Finally what if I don't have a flat surface. Imagine if I have a concave surface. I have some ideas but I can't seem to get through these initial problems.