SUMMARY

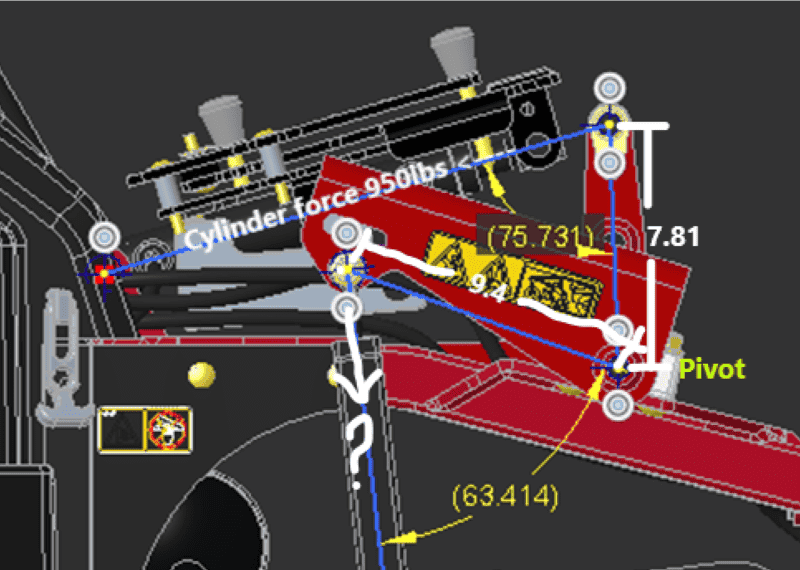

The discussion focuses on determining the downward force exerted by a rod in a mechanical linkage system, specifically in an auto-leveling front-end loader mechanism. The user calculated moments using the formula M=950xCOS(75.732)x7.81 + (X)SIN(63.414)x9.4, resulting in a force of 1828 lbs, but questioned the accuracy of a 217 lbs result. Accurate calculations require detailed information about the linkage centers-of-mass, lengths between pins, and coordinates of fixed point pins on the loader frame to derive the bucket downforce as a function of hydraulic pressure.

PREREQUISITES

- Understanding of mechanical linkages and their configurations

- Knowledge of vector analysis in mechanics

- Familiarity with calculating moments and forces

- Experience with hydraulic systems and their pressure dynamics

NEXT STEPS

- Research the principles of mechanical linkages and their applications in machinery

- Learn about vector analysis techniques for resolving forces in mechanical systems

- Study the calculation of moments and their significance in engineering mechanics

- Explore hydraulic pressure calculations and their effects on mechanical systems

USEFUL FOR

Mechanical engineers, hydraulic system designers, and anyone involved in the design or analysis of machinery requiring precise force calculations.