- #1

downeast

- 11

- 11

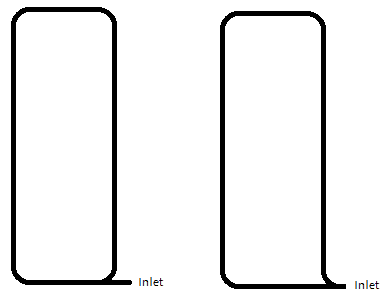

Which compressed air inlet to a ring (loop) pipeline would likely be best in terms of least turbulance and best flow (avoiding dead head)?

Given:

1) The inlet has to be in the corner of the rectangular loop.

2) Air consumption will be constant and evenly distributed throughout the loop.

3) The loop will be level.

Is the design on the left or the right better in the following diagram (or neither)?

Given:

1) The inlet has to be in the corner of the rectangular loop.

2) Air consumption will be constant and evenly distributed throughout the loop.

3) The loop will be level.

Is the design on the left or the right better in the following diagram (or neither)?