jsg94

- 8

- 0

Hello everyone,

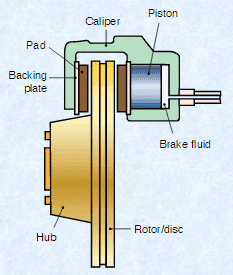

I'm currently working on a project where we need to change the little manual wheel (shown by red arrow) and replace it by a cylinder (either pneumatic or hydraulic). Right now, when the manual wheel is adjusted by rotating it to the right, the contracting rim will come closer together, which slows down the shaft that is rotating the white fabric seen in the image. What I'm trying to figure out is how to calculate the output force needed by the piston in order to successfully bring the contracting rim closer together.

I was looking for some ideas and I found the second image in this PDF (page 6) https://www3.nd.edu/~manufact/FME_pdf_files/FME3_Ch18.pdf . The rims are not in the same location, but I guess that gives you an idea of what I'm looking for. I attached a third image just in case.

I would really appreciate any ideas and general equations to estimate de force required by the piston, so I can select one with the right force range.

Thank you in advance for your help!

I'm currently working on a project where we need to change the little manual wheel (shown by red arrow) and replace it by a cylinder (either pneumatic or hydraulic). Right now, when the manual wheel is adjusted by rotating it to the right, the contracting rim will come closer together, which slows down the shaft that is rotating the white fabric seen in the image. What I'm trying to figure out is how to calculate the output force needed by the piston in order to successfully bring the contracting rim closer together.

I was looking for some ideas and I found the second image in this PDF (page 6) https://www3.nd.edu/~manufact/FME_pdf_files/FME3_Ch18.pdf . The rims are not in the same location, but I guess that gives you an idea of what I'm looking for. I attached a third image just in case.

I would really appreciate any ideas and general equations to estimate de force required by the piston, so I can select one with the right force range.

Thank you in advance for your help!

Last edited by a moderator: