Lesolee

- 8

- 0

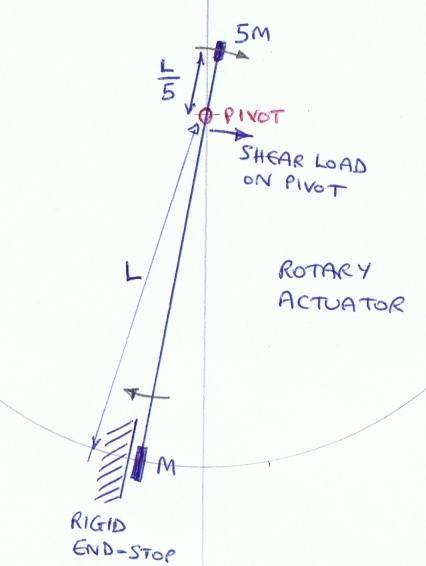

I have simplified the problem down to something like a physics textbook question, although this is a practical problem where the pivot on my rotary actuator has been damaged by a faulty driver which caused the armature to ram into the endstop.

Obviously this needs better protection. My problem is trying to relate the mechanics to the underlying physics.

Referring to the sketch, the mass M hits the endstop and decelerates pretty hard. The question is how to calculate the shear load on the pivot. Assume that the actuator is unpowered (not driven) when it hits the end stop and there are no other inertial loads than those shown.

If the end-stop were perfectly rigid and the armature were perfectly rigid I can imagine the mass 5M continuing with its tangential velocity. But that doesn’t give a load force. I think it is reasonable to assume that the armature is rigid. Suppose the end-stop decelerates the whole actuator by 10g as a tangential deceleration on the mass M. How would that transfer to the pivot as a force? The pivot doesn’t have much “give” in it.

Obviously this needs better protection. My problem is trying to relate the mechanics to the underlying physics.

Referring to the sketch, the mass M hits the endstop and decelerates pretty hard. The question is how to calculate the shear load on the pivot. Assume that the actuator is unpowered (not driven) when it hits the end stop and there are no other inertial loads than those shown.

If the end-stop were perfectly rigid and the armature were perfectly rigid I can imagine the mass 5M continuing with its tangential velocity. But that doesn’t give a load force. I think it is reasonable to assume that the armature is rigid. Suppose the end-stop decelerates the whole actuator by 10g as a tangential deceleration on the mass M. How would that transfer to the pivot as a force? The pivot doesn’t have much “give” in it.