Press Tonnage (No Flywheel)

- Thread starter Bob Warren

- Start date

-

- Tags

- Flywheel

Click For Summary

Discussion Overview

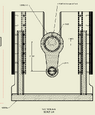

The discussion revolves around calculating the press tonnage for a mechanical system with specified stroke and operational parameters. Participants explore the necessary considerations for determining forces involved in the system, including the importance of a free body diagram and various mechanical properties of the ram and die.

Discussion Character

- Technical explanation, Mathematical reasoning, Debate/contested

Main Points Raised

- One participant mentions the stroke length of 2.00 inches and a frequency of 300 strokes per minute.

- Another participant specifies a position of 1/32 inch from bottom dead center (BDC).

- A participant questions whether the inquiry is homework-related and emphasizes the need for a free body diagram to proceed with calculations.

- One participant calculates crank torque and estimates the tonnage based on the provided torque value, suggesting a result of approximately 48.37 short tons, but expresses uncertainty without a diagram.

- Several participants highlight the importance of additional specifications such as ram dimensions, die opening width, material thickness, and type of material for accurate calculations.

- Another participant argues that certain parameters, like die opening width and material thickness, may not significantly affect the total tonnage calculation given the specified conditions.

- A detailed calculation is provided, showing the relationship between crank throw, angle, and mechanical advantage, leading to an estimated ram force of 48.25 short tons, while noting the potential impact of connecting rod length on this estimate.

- Concerns are raised about the necessity of a cushioned die to protect mechanical components, indicating that this would affect the actual tonnage applied to the work.

Areas of Agreement / Disagreement

Participants express varying opinions on the relevance of certain parameters in the calculations, and there is no consensus on the final tonnage value or the importance of specific details in the problem setup.

Contextual Notes

Participants note that the accuracy of calculations depends on the correctness of the free body diagram and the specifications provided, which are currently incomplete.

Similar threads

- · Replies 9 ·

Automotive

Why flywheels are needed in automobiles?

- · Replies 22 ·

- · Replies 9 ·

- · Replies 19 ·

- · Replies 3 ·

- · Replies 3 ·