- #1

birddseedd

- 5

- 0

I am in the process of designing a hitch for my motorcycle.

Realistically it is strong enough unless i pull more weight than i really should. That said I still should make it stronger in case of the foreseen, like when i got rear ended.

Before i get to the pictures, what I have now is strong enough to pull a 580 lb bike behind my bike, as well as the 40 50 lb trailer. Its a bit too much weight, however this is the problem. It can hold the weight just fine, but if there is much force applied in a forward motion, for example when i got rear ended, or when i had to push start the bike while attached via trailer the 2 lower arms get bent thus demolishing the hitch.

Mainly what I am asking is for some advice as to design it. There really isent anywhere to attach it other than the subframe (seat) and bolted into where the rear foot pegs bolt into. With the new design (created in photshop) I worry about 2 things. 1, the part of the hitch that holds the ball will no longer have as much support, 2, the old design had 2 square bars holding it from moving left and right, now i have a plate above the wheel that may or may not be enough to hold it from moving left and right.

Thank you for your help.

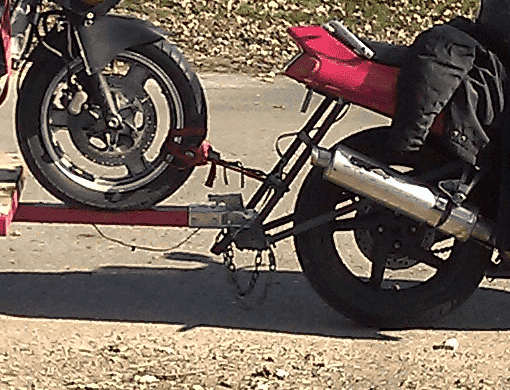

Current design (currently demolished by front and back motion)

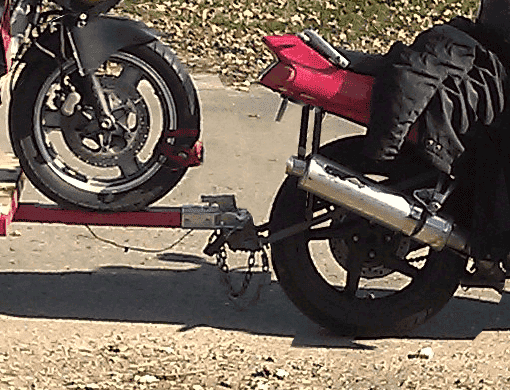

This is the proposed design, I am also thinking of goign to the metal supply for grade 8 steel rather than whatever home depot is selling.

remember, photoshoped so doesent look perfect.

Thanks again for your advice.

Realistically it is strong enough unless i pull more weight than i really should. That said I still should make it stronger in case of the foreseen, like when i got rear ended.

Before i get to the pictures, what I have now is strong enough to pull a 580 lb bike behind my bike, as well as the 40 50 lb trailer. Its a bit too much weight, however this is the problem. It can hold the weight just fine, but if there is much force applied in a forward motion, for example when i got rear ended, or when i had to push start the bike while attached via trailer the 2 lower arms get bent thus demolishing the hitch.

Mainly what I am asking is for some advice as to design it. There really isent anywhere to attach it other than the subframe (seat) and bolted into where the rear foot pegs bolt into. With the new design (created in photshop) I worry about 2 things. 1, the part of the hitch that holds the ball will no longer have as much support, 2, the old design had 2 square bars holding it from moving left and right, now i have a plate above the wheel that may or may not be enough to hold it from moving left and right.

Thank you for your help.

Current design (currently demolished by front and back motion)

This is the proposed design, I am also thinking of goign to the metal supply for grade 8 steel rather than whatever home depot is selling.

remember, photoshoped so doesent look perfect.

Thanks again for your advice.