Discussion Overview

The discussion revolves around a personal art project involving the mechanization of flower petals, specifically focusing on the challenges of ensuring the string mechanism operates continuously for an extended period without fraying or breaking. The conversation includes technical aspects of the setup, materials used, and potential engineering solutions.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

Main Points Raised

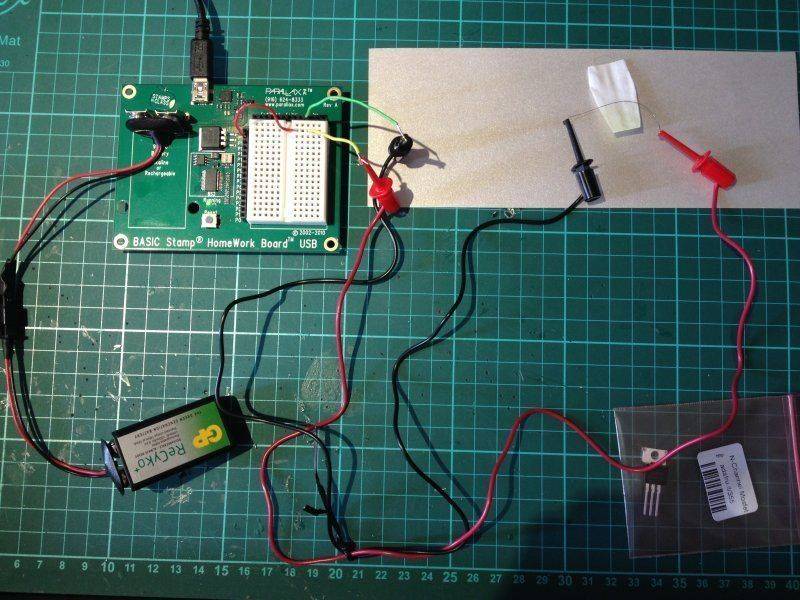

- Chris describes the project goal of mechanizing flower petals using a braided fishing line and various tubing to minimize friction and wear.

- Some participants suggest that the choice of materials and the setup may be overly complex, arguing that the fishing line should not fray under normal conditions if properly managed.

- Concerns are raised about the need for adjustability in the string setup, with suggestions for alternatives like using a turnbuckle or a progressive spring to manage tension.

- Participants discuss the importance of avoiding lateral motion of the string against surfaces to prevent failure, recommending the use of grommets and ensuring smooth transitions.

- There is a suggestion to consider using shape-memory metal wires instead of string for a more reliable mechanism.

- Chris expresses uncertainty about the sustainability of the current setup and seeks advice on potential failure points.

Areas of Agreement / Disagreement

Participants express differing views on the effectiveness and necessity of the current setup, with some suggesting simpler alternatives while others support the complexity of Chris's approach. The discussion remains unresolved regarding the best method to achieve the project's goals without string failure.

Contextual Notes

There are limitations in the discussion regarding the assumptions made about material properties and the specific mechanics of the setup, as well as the lack of detailed visual evidence of the flower's movement.

Who May Find This Useful

Individuals interested in mechanical design, robotics, or art projects involving automation may find the discussion relevant.