Discussion Overview

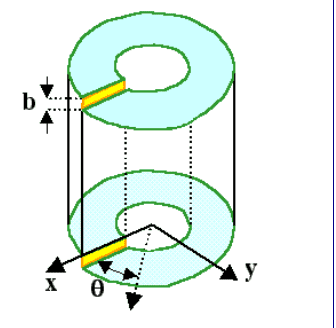

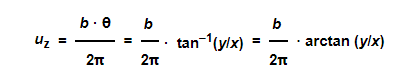

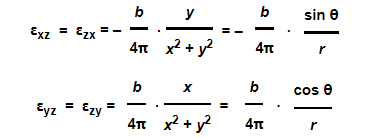

The discussion revolves around the behavior of screw dislocations in materials, specifically focusing on the displacement and strain fields associated with them. Participants explore the nature of discontinuities in the displacement field and the implications for strain continuity, within the context of continuum mechanics and dislocation theory.

Discussion Character

- Technical explanation

- Debate/contested

- Mathematical reasoning

Main Points Raised

- One participant questions how a discontinuous displacement field can still yield a continuous strain field across the dislocation surface.

- Another participant asserts that the arctangent function is not discontinuous and emphasizes that the stress should remain continuous except at the dislocation line.

- A later reply acknowledges the displacement jump but suggests that the strain field is defined in terms of final equilibrium coordinates, indicating that the "step" is incorporated into the formalism.

- Another participant references a textbook that describes the displacement 'step change' as plastic deformation, proposing that the total displacement field is a combination of continuous elastic displacement and discontinuous plastic displacement.

Areas of Agreement / Disagreement

Participants express differing views on the nature of displacement and strain fields in the context of screw dislocations. There is no consensus on how discontinuities in displacement relate to strain continuity, and multiple competing interpretations are presented.

Contextual Notes

Participants note that the definitions of displacement and strain fields may depend on the context of the model being used, and there are unresolved aspects regarding the behavior at the dislocation center.