- #1

thereddevil

- 26

- 1

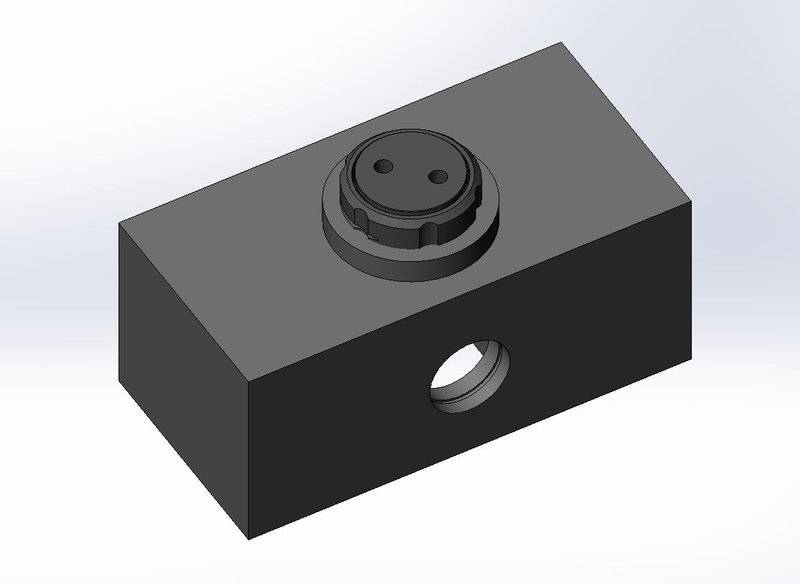

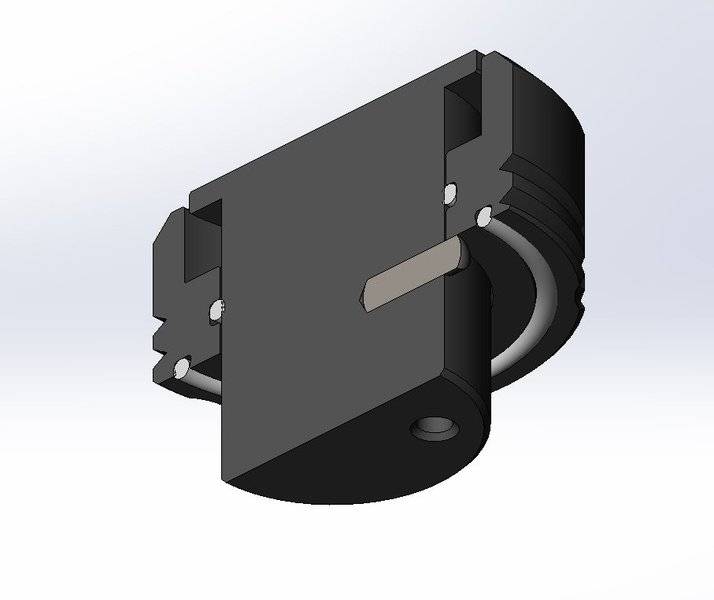

I am working on a design where I have a block which has a cap assembly fitted to it - see images attached.

The cap assembly is constructed of:

- Main body with two holes through (flowing water in and out)

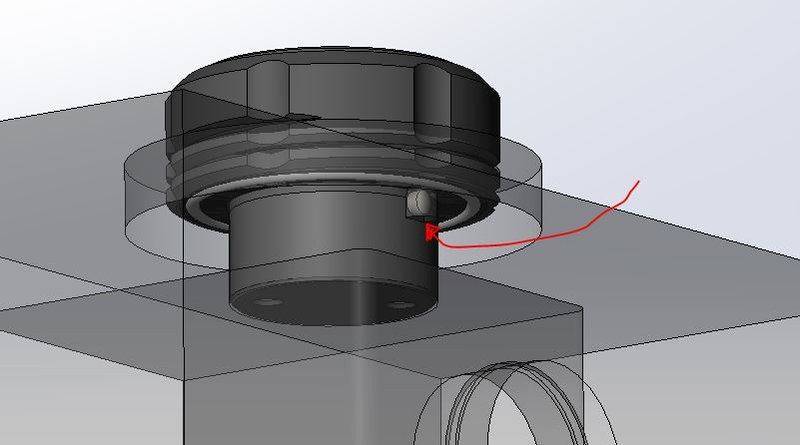

- Locking ring with a threaded outside, grooves for tightening by hand and two o-rings (face seal and rod seal)

- Dowel pin for alignment (important that the flowing water comes in and out in particular orientation)

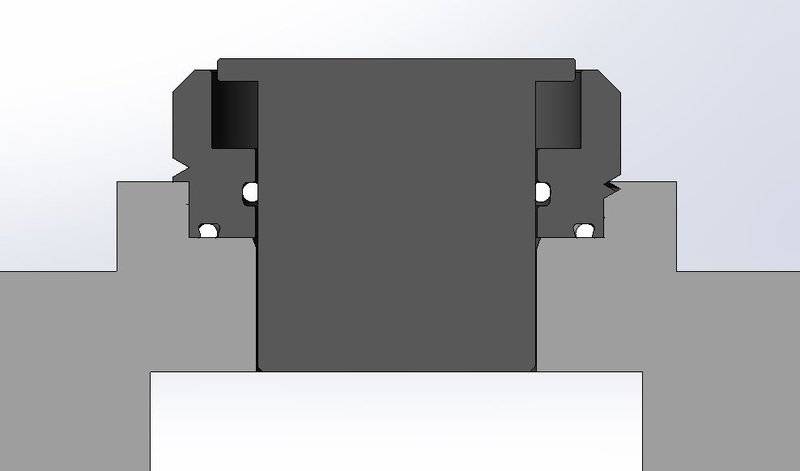

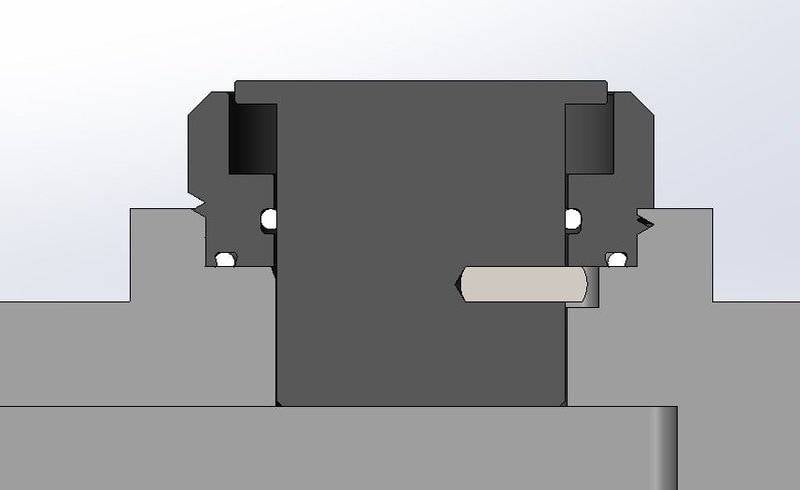

The block has the following features:

- Threaded entry for locking ring

- Alignment slot for dowel pin to sit in

- Flat face for face seal to sit against

It has been designed so that as the cap assembly is dropped into the block, the dowel pin must first be aligned to the slot in the block before you are able to screw the locking ring. Materials:

all to be Delrin/Acetal at present. Block will be fixed as Delrin due to other requirements, but cap's main body/locking ring could be other plastics. The pressure inside will be a minimal negative pressure (i.e. water is being pulled out of the space under the cap rather than pushed through). Locking ring outside diameter is Ø40mm for an indication of scale.

Now the questions...

The o-ring that sits between the cap's main body and locking ring must allow the two parts to rotate relative to each other. Previous experience from colleagues of mine show that there can be a significant amount of friction here with a nitrile o-ring as well as acetal on acetal mating threaded parts. Any lubrication of the o-rings will quickly be removed through use and cannot be relied upon.

- What can be done to reduce this friction?

- O-ring material change to say PTFE/Nylon?

- Rotary seals?

- What materials could the cap use to prevent binding to the block?

Thanks in advance!

The cap assembly is constructed of:

- Main body with two holes through (flowing water in and out)

- Locking ring with a threaded outside, grooves for tightening by hand and two o-rings (face seal and rod seal)

- Dowel pin for alignment (important that the flowing water comes in and out in particular orientation)

The block has the following features:

- Threaded entry for locking ring

- Alignment slot for dowel pin to sit in

- Flat face for face seal to sit against

It has been designed so that as the cap assembly is dropped into the block, the dowel pin must first be aligned to the slot in the block before you are able to screw the locking ring. Materials:

all to be Delrin/Acetal at present. Block will be fixed as Delrin due to other requirements, but cap's main body/locking ring could be other plastics. The pressure inside will be a minimal negative pressure (i.e. water is being pulled out of the space under the cap rather than pushed through). Locking ring outside diameter is Ø40mm for an indication of scale.

Now the questions...

The o-ring that sits between the cap's main body and locking ring must allow the two parts to rotate relative to each other. Previous experience from colleagues of mine show that there can be a significant amount of friction here with a nitrile o-ring as well as acetal on acetal mating threaded parts. Any lubrication of the o-rings will quickly be removed through use and cannot be relied upon.

- What can be done to reduce this friction?

- O-ring material change to say PTFE/Nylon?

- Rotary seals?

- What materials could the cap use to prevent binding to the block?

Thanks in advance!