Builder89

- 28

- 0

Thanks everyone for the help. I think I'm good to go now. :-)

The discussion revolves around calculating the forces acting on a bicycle's suspension system, specifically focusing on the vertical force applied to the shock absorber when the bike is at rest and when it impacts the ground after a fall. Participants explore the dynamics of force transmission through the swing arm and linkage, considering various scenarios of weight distribution and impact forces.

Participants express differing views on the correct method for calculating forces and the implications of energy versus force. There is no consensus on the approach to determining Fav or the impact of the fall on the forces involved.

Participants acknowledge the presence of additional forces, such as friction, and the need for practical adjustments in real-world applications. The discussion highlights the complexity of accurately modeling suspension dynamics and the various factors that influence the calculations.

This discussion may be useful for individuals interested in bicycle mechanics, suspension design, and the physics of forces in dynamic systems.

OK, but I'd like to be confident you are calculating the torques correctly: ##\tau = Fr\sin(\theta)##Builder89 said:Thanks everyone for the help. I think I'm good to go now. :-)

Builder89 said:FR(cos12)(495) = FM(cos12)(102)

No, you have to treat FR and FS as two forces acting at different angles on the arm, balancing:Builder89 said:The force into the shock, FS = cos40(458.60)

Actually I was a bit wrong, but not in the way you think.Builder89 said:Hmmm, really? I feel you're wrong. FL is the pivot point, O. FM and FR are torque forces working to twist around FL in opposite directions.

Because part of the compression force on the shock comes from the reaction force at the pivot.Builder89 said:why can't I get the same FS using the following?

Sure, but that is just the vertical component of FS.Builder89 said:why can't FM be isolated as output from the swing arm diagram and fed into some other mechanism after the fact as a vertical force?

I think you mean FR, not FM.JBA said:FS = 495/102 * FM * cos 12 / cos 52° = 7.71 FM

But:haruspex said:FS cos 40 = FM

In your diagram in post #39, there are three forces acting where the shock meets the arm: FS, FM and the compression in the arm. You seem to be resolving in the direction parallel to the shock, but if you do that you must include the compression in the arm. Simpler to resolve normal to the arm.Builder89 said:cos(theta) = adj/hyp.

Why?Builder89 said:I'm trying to find the FM

This is what I have tried to explain in posts #42 and #45.Builder89 said:Apparently my method is wrong so I'm trying to understand why

haruspex said:FS cos(52) (102)=FR cos(12) (495).

So FS=7.7 FR.

In the drop scenario, you cannot compute FM independently of the shock behaviour.Builder89 said:How do I do the same thing for the linkage triangle in post 46? I'm not sure where to start to get FM.

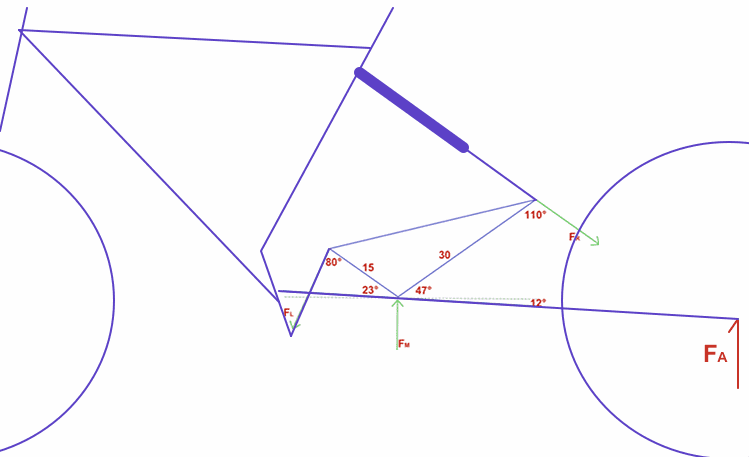

I believe your force diagram for the linkage in post #46 is wrong. (If correct it would be overspecified, with two unknowns, the magnitudes of the two forces, but three equations.)Builder89 said:Here is a rough representation of the context it goes in. All points on the triangle are pivots. FL is a rod attached to the frame on the bottom via another pin (pivot). The shock is only connected at the right point on the triangle and the frame up and left. Remember, we are doing the calculation in equilibrium at this point with the shock compressed 76mm. As such, this is how it looks. All numbers are mm.

And, as stated before, the FA is just the portion of weight on the bike that is at the rear tire.