smr101

- 72

- 0

Thread moved from the technical engineering forums, so no Homework Help Template is shown

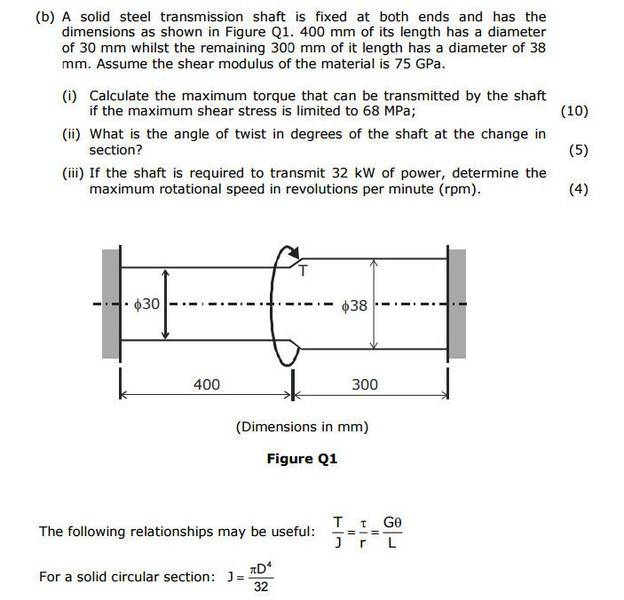

Hi,

Struggling with calculating the angle of twist, using TL/GJ.

The answer to (b)(i) is 946.1 Nm.

Using 0.3 m length section.

946.1 * 0.3 / 75 x 10^9 * 2.047 x 10^-7

= 0.0185 * 180/pi

= 1.06 rads

Answer is 0.273.

Question below (b)(ii):

Struggling with calculating the angle of twist, using TL/GJ.

The answer to (b)(i) is 946.1 Nm.

Using 0.3 m length section.

946.1 * 0.3 / 75 x 10^9 * 2.047 x 10^-7

= 0.0185 * 180/pi

= 1.06 rads

Answer is 0.273.

Question below (b)(ii):

Last edited: