DefinitelyAnEnjinear

- 10

- 6

- TL;DR

- stuck on a problem of designing a mechanism translating linear to rotary motion; mechanisms like a crank are unsuitable for my purposes

I'm trying to design a mechanism to translate reciprocating motion into a 45 degree rotation.

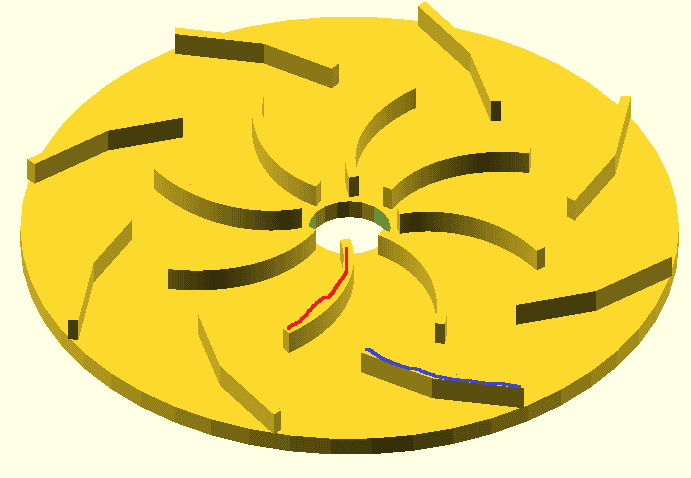

Here's the idea:

A pin will push against the part marked in red, causing part of the desired rotation. Then, when the pin is pulled back, its interaction with the blue part will complete a 45 degree rotation. since the object is rotationally symmetric, another back-and-forth motion will yield the same result

The problem with this particular design is that I don't know it actually leads to a 45 degree rotation. I designed and printed this just to make sure the idea will work with no idea how to optimally design something like this.

I am now slightly wiser thanks to this forum, but not wise enough.

I'm guessing the optimal design would use two segments of a logarithmic spiral (for the part marked in red and the part marked in blue), one with k=1 (to create a constant 45 degree angle on the forward motion) and one with k=-1 (for a 45 degree angle on the backward motion of the pin).

My main problem is... how do I position the second spiral segment (corresponding to the one marked in blue)?

I can think of a few constraints:

Why not use an existing mechanism, like a crankshaft with an 8:1 gear reduction?

Well, I have yet to come across a suitable mechanism that satisfies the condition that the part driving it be able to disengage from it (in the case of my design, the pin would leave the area of the disc once the 45 degree rotation is complete)

Here's the idea:

A pin will push against the part marked in red, causing part of the desired rotation. Then, when the pin is pulled back, its interaction with the blue part will complete a 45 degree rotation. since the object is rotationally symmetric, another back-and-forth motion will yield the same result

The problem with this particular design is that I don't know it actually leads to a 45 degree rotation. I designed and printed this just to make sure the idea will work with no idea how to optimally design something like this.

I am now slightly wiser thanks to this forum, but not wise enough.

I'm guessing the optimal design would use two segments of a logarithmic spiral (for the part marked in red and the part marked in blue), one with k=1 (to create a constant 45 degree angle on the forward motion) and one with k=-1 (for a 45 degree angle on the backward motion of the pin).

My main problem is... how do I position the second spiral segment (corresponding to the one marked in blue)?

I can think of a few constraints:

- have a line from the center of the circle, going through both the end of the red segment (the part closest to the center) and intersecting the blue segment - to guarantee that the pin will interact with the blue segment on the backward motion

- Have a line from the center of the circle, going through the end of the blue segment and the beginning of the next copy of the red segment - to guarantee that when the forward motion happens, we engage again

Why not use an existing mechanism, like a crankshaft with an 8:1 gear reduction?

Well, I have yet to come across a suitable mechanism that satisfies the condition that the part driving it be able to disengage from it (in the case of my design, the pin would leave the area of the disc once the 45 degree rotation is complete)