SofiaB

- 2

- 0

- TL;DR

- Hello everyone! I am just trying to verify if the results I obtained for my truss behaviour analysis are correct

Hello everyone!

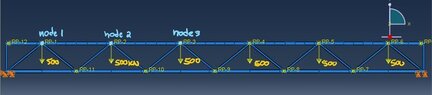

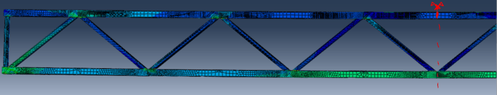

I am analysing an 18 m per 1.2 m truss, simply supported, with 140x5 chords and 90x8 braces. I then loaded the superior nodes with 500 KN. The top nodes were also laterally constrained to prevent out-of-plane displacements.

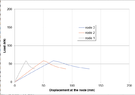

After imputing the structure in Abaqus (FEA software), I obtained the load-displacement curves in the top nodes where the concentrated loads were applied. I should note that I am doing a nonlinear analysis with a nonlinear material(S355).

What I found weird was the abrupt drop in the curve after yielding, as well as the fact that the value of the yielding strength seems very small. Can someone help me understand if this behaviour is correct? I will leave some pictures of the truss, the material input and the load-displacement curves for each node for better understatement.

Should also note that ultimately what I am studying is the joints behaviour (in a further analysis I will increase their rigidity) and thus I want to explore the behaviour above the yield limit.

Thanks in advance!

I am analysing an 18 m per 1.2 m truss, simply supported, with 140x5 chords and 90x8 braces. I then loaded the superior nodes with 500 KN. The top nodes were also laterally constrained to prevent out-of-plane displacements.

After imputing the structure in Abaqus (FEA software), I obtained the load-displacement curves in the top nodes where the concentrated loads were applied. I should note that I am doing a nonlinear analysis with a nonlinear material(S355).

What I found weird was the abrupt drop in the curve after yielding, as well as the fact that the value of the yielding strength seems very small. Can someone help me understand if this behaviour is correct? I will leave some pictures of the truss, the material input and the load-displacement curves for each node for better understatement.

Should also note that ultimately what I am studying is the joints behaviour (in a further analysis I will increase their rigidity) and thus I want to explore the behaviour above the yield limit.

Thanks in advance!