mellotango

- 33

- 0

Hi,

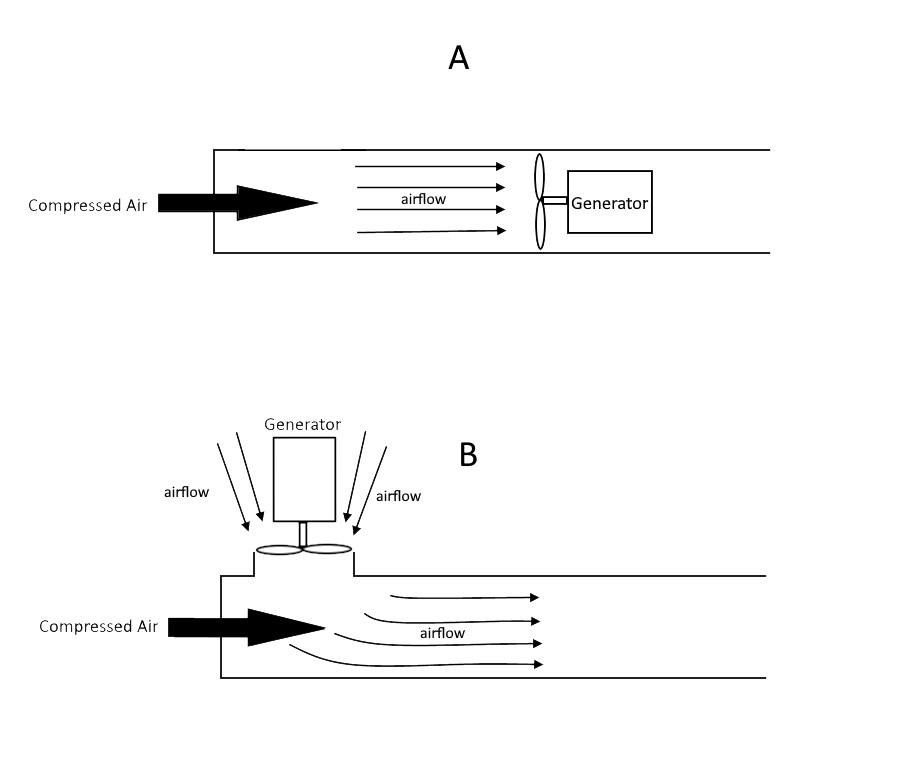

I am trying to figure out the strength of the various type of airflow for my Venturi ejector device. Please refer to my diagram that illustrates scenario A or scenario B. The SAME amount of compressed air is injected for both scenario A and B. For simplicity, I have added to an electrical generator to measure the strength or power of the airflow.

1. I would like to know which scenario (A or B) would generate more power with the generator.

2. And by what factor would the difference in power level of the airflows between A and B?

I am trying determine if the power of sucked air flow is better, equal or worse than the power of direct air flow. If any engineers can help me out with the calculations, I would greatly appreciate it.

Thanks in advance!

p.s. sorry, i made a quick change to drawing A

I am trying to figure out the strength of the various type of airflow for my Venturi ejector device. Please refer to my diagram that illustrates scenario A or scenario B. The SAME amount of compressed air is injected for both scenario A and B. For simplicity, I have added to an electrical generator to measure the strength or power of the airflow.

1. I would like to know which scenario (A or B) would generate more power with the generator.

2. And by what factor would the difference in power level of the airflows between A and B?

I am trying determine if the power of sucked air flow is better, equal or worse than the power of direct air flow. If any engineers can help me out with the calculations, I would greatly appreciate it.

Thanks in advance!

p.s. sorry, i made a quick change to drawing A

Last edited: