DonKiwi

- 6

- 5

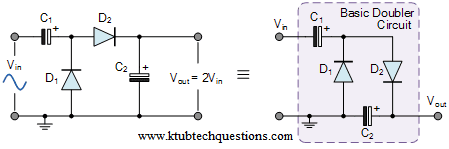

I am trying to build a Voltage Doubler to use a motorcycle 6 Volt a.c. alternator's dedicated headlight coil (which presently runs a 36W incandescent headlight bulb) to provide 12 Volt d.c. to drive a commercially-bought 12V LED headlight unit (also rated at 36W). Frequency will be (1500 ~ 5000 r.p.m * 60) 90kHz ~ 300 kHz.

I want to use the Greinacher circuit configuration

to allow common Earth between alternator and headlight. This will avoid any alteration to the Alternator internal wiring or the added complication of a floating 12V d.c.output above chassis ground (as would be necessary in "Bridge" or "Full-Wave" configurations).

It will also give full reversibility to enable restoration of the bike's wiring to factory standard by simply removing the Voltage Doubler unit from its series connections in the wiring loom.

I have searched online in vain to find guidance for the purpose of establishing Diode and Capacitor values for the proposed Current and Frequency range, or even sufficient information to ascertain if this project is indeed feasible.

All assistance, comments and criticism is invited.

I want to use the Greinacher circuit configuration

to allow common Earth between alternator and headlight. This will avoid any alteration to the Alternator internal wiring or the added complication of a floating 12V d.c.output above chassis ground (as would be necessary in "Bridge" or "Full-Wave" configurations).

It will also give full reversibility to enable restoration of the bike's wiring to factory standard by simply removing the Voltage Doubler unit from its series connections in the wiring loom.

I have searched online in vain to find guidance for the purpose of establishing Diode and Capacitor values for the proposed Current and Frequency range, or even sufficient information to ascertain if this project is indeed feasible.

All assistance, comments and criticism is invited.