Discussion Overview

The discussion revolves around the difficulties encountered when replacing a standard screw with a knob-like screw, specifically an M6 type. Participants explore reasons why the replacement knob does not tighten properly, potential solutions for modifying the knob, and the availability of specialized screws.

Discussion Character

- Technical explanation

- Debate/contested

- Experimental/applied

Main Points Raised

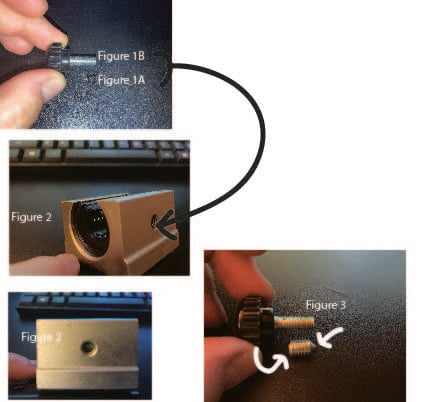

- One participant notes that while the original screw tightens well, the replacement knob does not, despite both being M6 types.

- Another suggests that the replacement knob may have poorly formed threads due to its manufacturing process.

- Some participants propose grinding the end of the knob to create a point, discussing various tools for this task, including angle grinders and Dremel tools.

- There are inquiries about whether the original screw could be a different thread type, such as 1/4"-28, and how to check for compatibility between threads.

- Participants discuss the precision required for grinding the knob and suggest methods to achieve a centered point.

- One participant mentions the possibility of purchasing pointed metric setscrews and knobs from suppliers like McMaster-Carr.

- There are questions about the manufacturing processes for creating cone-point screws and the tools that might be used.

Areas of Agreement / Disagreement

Participants express various viewpoints on the reasons for the replacement knob's failure to tighten properly, with no consensus reached on the best solution or the exact cause of the issue. Multiple competing views on the appropriate tools and methods for modification are presented.

Contextual Notes

Participants highlight the potential for differences in thread pitch and condition of the threaded hole, which may affect compatibility. There are also discussions about the limitations of available tools and the precision required for modifications.

Who May Find This Useful

This discussion may be useful for individuals working with screws and knobs in mechanical applications, DIY enthusiasts, and those interested in fastener compatibility and modification techniques.