Discussion Overview

The discussion revolves around the effectiveness of different types of fans, specifically centrifugal versus axial fans, for moving air through a small diameter hose connected to a plastic box. Participants explore the implications of fan design on airflow, pressure, and noise levels in this context.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

- Experimental/applied

Main Points Raised

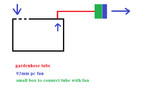

- One participant questions whether a centrifugal fan would be more effective than an axial fan for pushing air through a 2cm hose, given the axial fan's design for high flow and low static pressure.

- Another participant asserts that a centrifugal blower is indeed better for this application due to its ability to develop pressure, which is necessary for overcoming the resistance of the hose.

- A participant mentions testing a small centrifugal blower and expresses uncertainty about its performance compared to two 92mm axial fans, considering its smaller size.

- Concerns are raised about the noise produced by the axial fans when constrained by the hose, attributed to stalled blades and inefficient turbulence.

- Discussion includes the potential benefits of using both intake sides of the blower fan to optimize airflow.

- One participant suggests that the airflow is primarily limited by the hose outlet rather than the fan inlet, indicating that modifications to the setup could improve performance.

- Another participant introduces the concept of comparing fan curves to predict airflow performance, emphasizing the importance of understanding the system curve in relation to fan characteristics.

Areas of Agreement / Disagreement

Participants express differing opinions on the effectiveness of centrifugal versus axial fans, with some supporting the use of centrifugal fans for higher pressure applications while others remain uncertain about the performance comparison. The discussion does not reach a consensus on the optimal fan choice.

Contextual Notes

Participants mention various factors affecting airflow, including fan design, hose diameter, and system configuration, but do not resolve the implications of these factors on performance outcomes.

Who May Find This Useful

This discussion may be useful for individuals interested in fan performance, airflow dynamics, and practical applications in ventilation or cooling systems, particularly in constrained environments.