moegilla

- 1

- 0

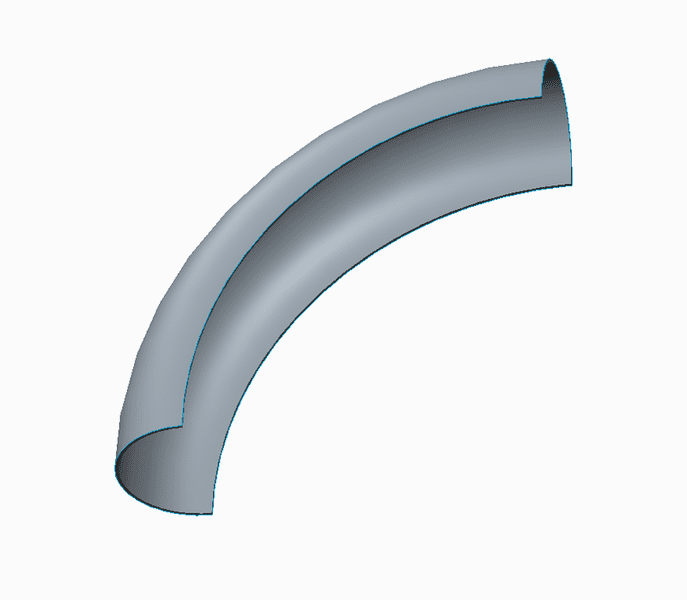

Invention prototype -- help please with bent half tube...

Hi all,

I am in the prototype phase of an invention and I need part that I can't get made and was looking for a few ideas.

As you can see the part is double-curved 16 gauge sheet metal. I brought it to a sheet metal shop and the guy told me it would cost an arm and a leg for 1, let alone the 4 I need.

I started thinking I could find a 90 degree elbow of some sort and cut it in half.

Any ideas?

Hi all,

I am in the prototype phase of an invention and I need part that I can't get made and was looking for a few ideas.

As you can see the part is double-curved 16 gauge sheet metal. I brought it to a sheet metal shop and the guy told me it would cost an arm and a leg for 1, let alone the 4 I need.

I started thinking I could find a 90 degree elbow of some sort and cut it in half.

Any ideas?

Last edited by a moderator: