- #1

PRIDES

- 20

- 0

There is a recent project I have been working on that requires the use of Isobutane as a propellant/solvent, so I have come up with a way to study the chemical compatibility of isobutane:

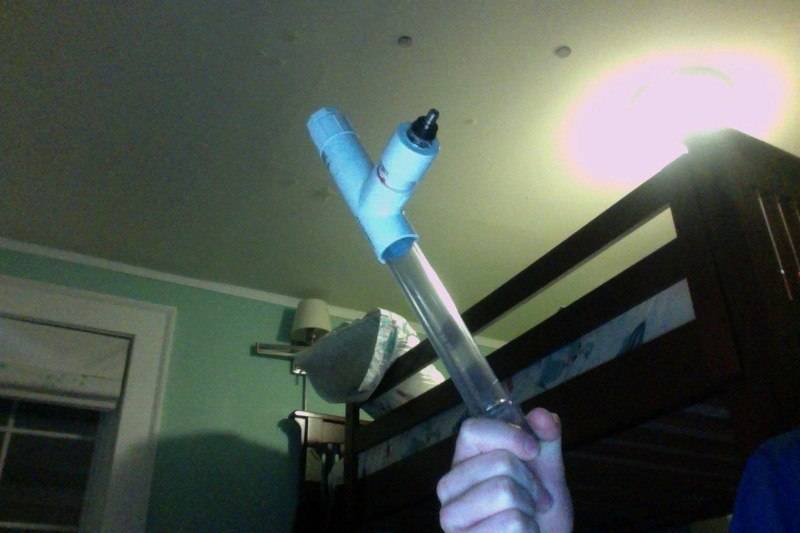

I have a pressure chamber that I built from transparent PVC and opaque PVC with a tire valve as an inlet for air and isobutane:

I use r600a refrigerant for isobutane (420 grams, 720 liters)

I can put solid objects into the top of the chamber.

I use anti-air loss tire valve connectors.

The procedure is as follows:

1. connect r600a refrigerant canister to pressure chamber and wait a little bit.

2. remove the connection quickly.

3. connect air compressor to the pressure chamber and pressurize to 50 psi.

4. optional: remove the connection quickly.

I know that the vapor pressure of Isobutane is about 43 psi, so I should see a liquid in the chamber, but I don't. Please this is making no sense to me.

I have a pressure chamber that I built from transparent PVC and opaque PVC with a tire valve as an inlet for air and isobutane:

I use r600a refrigerant for isobutane (420 grams, 720 liters)

I can put solid objects into the top of the chamber.

I use anti-air loss tire valve connectors.

The procedure is as follows:

1. connect r600a refrigerant canister to pressure chamber and wait a little bit.

2. remove the connection quickly.

3. connect air compressor to the pressure chamber and pressurize to 50 psi.

4. optional: remove the connection quickly.

I know that the vapor pressure of Isobutane is about 43 psi, so I should see a liquid in the chamber, but I don't. Please this is making no sense to me.

Last edited: