- #1

Woldennis

- 10

- 4

Hi all,

I am new to the forum and hoping for some help please.

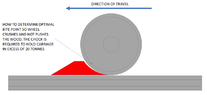

I work in the rail industry and we use chock blocks to stop trains or carriages rolling. I would like to know about the technical side of how and why the chock stops the wheel from moving. Obviously it wedges the wheel to stop movement but i am keen to learn what is the optimal point in terms of angle of slope required depending on the wheel size etc. From testing them i know that too step of a slope is detrimental as the wheel pushes and not crushes the wood so the block slides along but surely there must be some calculation that determines the optimal point to wedge a wheel etc.

I have seen simpack software that looks like it could provide some insight in helping with testing and providing data etc but have no idea where to begin.

So what i am kind of asking is there anyone that can provide some insight and help teach me some basics of how to calculate stuff like this or if simpack is even the correct thing i should be looking at.

Thanks in advance

I am new to the forum and hoping for some help please.

I work in the rail industry and we use chock blocks to stop trains or carriages rolling. I would like to know about the technical side of how and why the chock stops the wheel from moving. Obviously it wedges the wheel to stop movement but i am keen to learn what is the optimal point in terms of angle of slope required depending on the wheel size etc. From testing them i know that too step of a slope is detrimental as the wheel pushes and not crushes the wood so the block slides along but surely there must be some calculation that determines the optimal point to wedge a wheel etc.

I have seen simpack software that looks like it could provide some insight in helping with testing and providing data etc but have no idea where to begin.

So what i am kind of asking is there anyone that can provide some insight and help teach me some basics of how to calculate stuff like this or if simpack is even the correct thing i should be looking at.

Thanks in advance