- #1

Anachronist

Gold Member

- 117

- 47

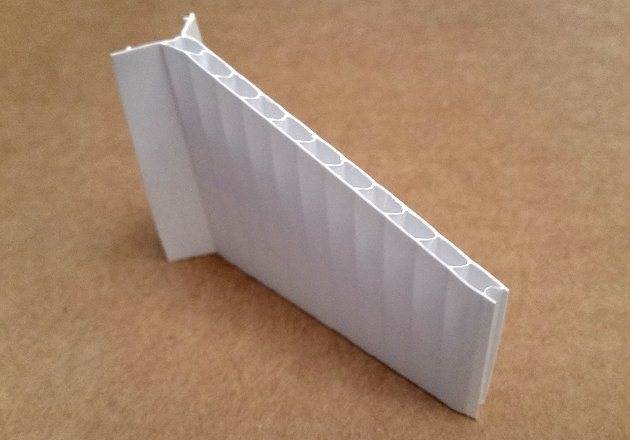

Here's a crude model rocket fin made out of a material called Coroplast (corrugated plastic):

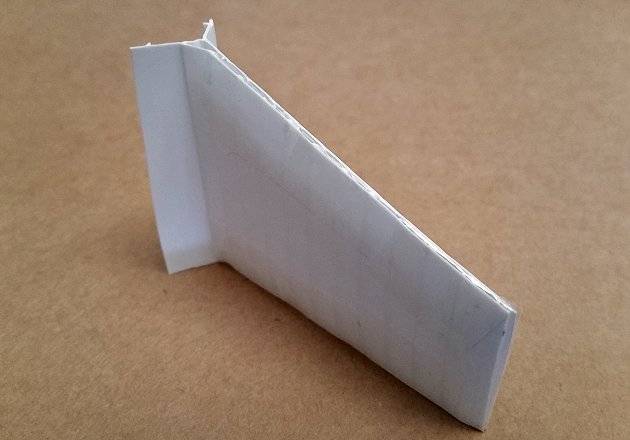

And here's the exact same fin with the flutes cut out from all around the edges, allowing the edges to be squeezed shut and sealed with tape:

It may look like there are small openings, but they're not openings, they're covered with clear tape.

My question is, which version would have the least drag?

Intuitively, my first thought was that the version with open edges has the least drag because it presents negligible frontal area (the top edge is the leading or windward edge).

Then I had second thoughts, which prompted me to seal the edges, but I'm still unsure. On one hand, the open version also has more than twice as much surface area as the version with closed edges. So maybe it has more drag. On the other hand, the version with closed edges has an order of magnitude larger frontal area. Then again, the closed-edge version is more or less airfoil shaped with tapered edges, so maybe it has less drag.

I don't really have any way to test this. I'm curious though, what would be the dominant contributor to drag? Surface area with negligible frontal area, or large frontal area of a somewhat streamlined shape?

If it matters, the fin is roughly 5 cm tall and 6 cm long, and is expected to experience a velocity of 76 m/s (170 mph).

And here's the exact same fin with the flutes cut out from all around the edges, allowing the edges to be squeezed shut and sealed with tape:

It may look like there are small openings, but they're not openings, they're covered with clear tape.

My question is, which version would have the least drag?

Intuitively, my first thought was that the version with open edges has the least drag because it presents negligible frontal area (the top edge is the leading or windward edge).

Then I had second thoughts, which prompted me to seal the edges, but I'm still unsure. On one hand, the open version also has more than twice as much surface area as the version with closed edges. So maybe it has more drag. On the other hand, the version with closed edges has an order of magnitude larger frontal area. Then again, the closed-edge version is more or less airfoil shaped with tapered edges, so maybe it has less drag.

I don't really have any way to test this. I'm curious though, what would be the dominant contributor to drag? Surface area with negligible frontal area, or large frontal area of a somewhat streamlined shape?

If it matters, the fin is roughly 5 cm tall and 6 cm long, and is expected to experience a velocity of 76 m/s (170 mph).