- #1

lamejane

- 11

- 2

- TL;DR Summary

- Solution to get rid of water in a vacuum chamber

Hello all ,

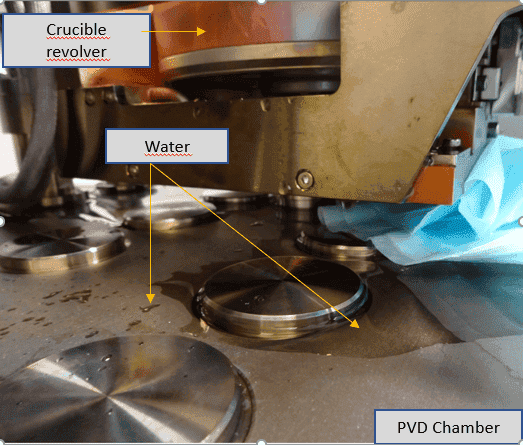

our PVD chamber experienced a water leakage from the cruible revoler area and unfortunately we are no longer able to achieve a stable Base pressure ( ~10e-6 mbar)

We do not have the option of a bake out. Is there any other way to get rid of water in the chamber ?

Ofcourse the water has been wiped out dry using clean room wipes, but i suspect there is still some monolayers of water adhering strongly to the chamber surface. Would repeated Nitrogen flusing help in getting rid of the water molecules? ?

Thanks !

Thanks !

Rgds

Jane

our PVD chamber experienced a water leakage from the cruible revoler area and unfortunately we are no longer able to achieve a stable Base pressure ( ~10e-6 mbar)

We do not have the option of a bake out. Is there any other way to get rid of water in the chamber ?

Ofcourse the water has been wiped out dry using clean room wipes, but i suspect there is still some monolayers of water adhering strongly to the chamber surface. Would repeated Nitrogen flusing help in getting rid of the water molecules? ?

Rgds

Jane