- #1

fitz_calc

- 41

- 0

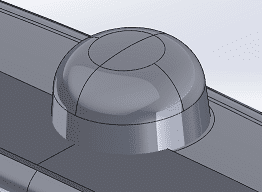

I have a small Lexan 141 dome I snap into a large piece of polycarbonate-ABS:

I'd prefer to adhere with some other method, are any of you materials guys familiar in welding technologies? Would something like ultrasonic or vibration welding be a possibility for me?

I'd prefer to adhere with some other method, are any of you materials guys familiar in welding technologies? Would something like ultrasonic or vibration welding be a possibility for me?