Stevengouws

- 9

- 2

- TL;DR

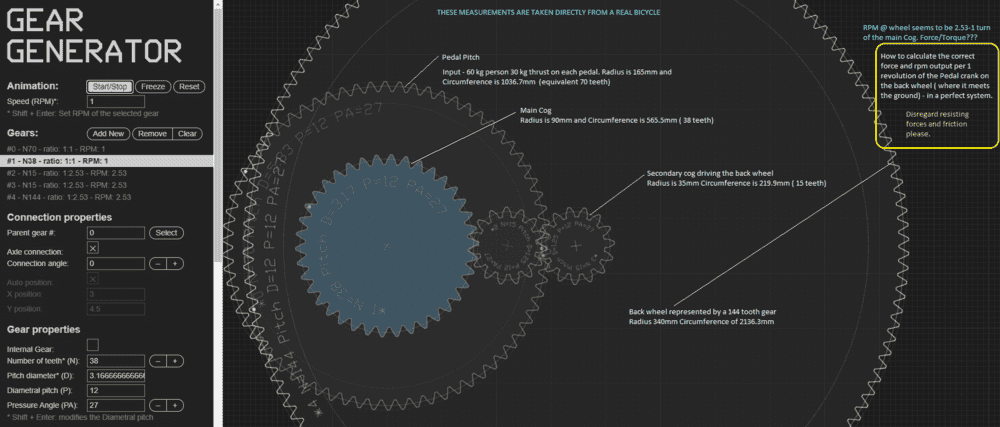

- What is the output of Torque on the driver wheel of a bicycle(where it meets tar), verse the input of torque on the pedal. I have all the sizes and forces, yet the correct formula eludes me.

A person weighing 60 kg exerts 30 kg of thrust on a pedal (crank) x 2 pedals = 60 kg of force per Revolution. Let's say @ 30 RPM.

What is the output kg of force per RPM on the back wheel where it meets the tar.

I have all the sizes and forces, yet the correct formula eludes me.

The ratio per 1 RPM of the pedal crank to wheel is 2.571

The Pedal ( Crank ) size is Radius 165mm and circumference of 1036.7mm or ( 70 teeth simplified )

The Main Driver cog is Radius 90mm and circumference of 565.5mm or ( 38 teeth )

The Secondary cog ( driving the back wheel ) is Radius 35mm and circumference of 219.9mm ( 18 teeth )

The back wheel is Radius 340mm and circumference of 2136.3mm ( 144 teeth )

Please see image to clarify

I am not interested in resisting forces or frictional forces - rather let's say these do not exist for this exercise, call it a perfect system.( I am still learning )

The online Gear generator Tool I found is a free useful tool for anyone interested:

https://geargenerator.com/#300,450,...,0,0,0,0,3,1,144,12,12,27,0,0,0,0,0,0,1,3,609

What is the output kg of force per RPM on the back wheel where it meets the tar.

I have all the sizes and forces, yet the correct formula eludes me.

The ratio per 1 RPM of the pedal crank to wheel is 2.571

The Pedal ( Crank ) size is Radius 165mm and circumference of 1036.7mm or ( 70 teeth simplified )

The Main Driver cog is Radius 90mm and circumference of 565.5mm or ( 38 teeth )

The Secondary cog ( driving the back wheel ) is Radius 35mm and circumference of 219.9mm ( 18 teeth )

The back wheel is Radius 340mm and circumference of 2136.3mm ( 144 teeth )

Please see image to clarify

I am not interested in resisting forces or frictional forces - rather let's say these do not exist for this exercise, call it a perfect system.( I am still learning )

The online Gear generator Tool I found is a free useful tool for anyone interested:

https://geargenerator.com/#300,450,...,0,0,0,0,3,1,144,12,12,27,0,0,0,0,0,0,1,3,609