Tusike

- 137

- 0

Hi!

For a university project I have to design a braking mechanism for a remote controlled car. I have very little experience in designing constructions, so I thought I'd ask here for any advice on the matter. I'm mostly curious about the design pattern, the thought process I should be going through.

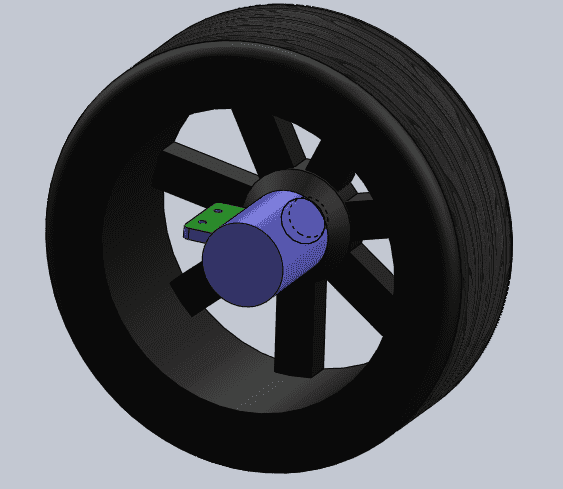

The following image illustrates the wheel, which rotates about a stationary component marked blue. Any construction should be attached to this, e.g. with two screws at the area marked green.

The inner diameter of the wheel is 8 cm, and I have a depth of about 4-5 cm to work in. Note however, that I didn't model how the wheel connects to the rest of the car, so the design should fit into the mid-left and upper-left sections of the space inside the wheel (the other parts are blocked).

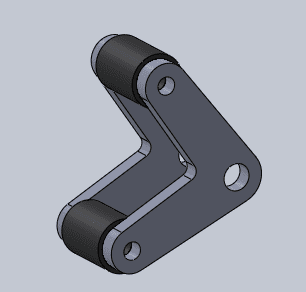

What would be the best brake construction in this situation? The braking force should be as adjustable as possible. I've thought about possible mechanical constructions, like fastening a small micro servo motor to the stationary part, and using a rack & pinion to push a rubber brake into the inner side of the wheel. Another idea was to use the motor to rotate the piece below, and press either of the two rubber cylinders against the wheel, depending on which direction it was rotating in. (This however, seems prone to breaking if you press the wrong side into the rotating wheel...)

Am I starting off in the right direction, are there any better constructions I should've thought of or I should look into? Any help is greatly appreciated.

-Tusike

For a university project I have to design a braking mechanism for a remote controlled car. I have very little experience in designing constructions, so I thought I'd ask here for any advice on the matter. I'm mostly curious about the design pattern, the thought process I should be going through.

The following image illustrates the wheel, which rotates about a stationary component marked blue. Any construction should be attached to this, e.g. with two screws at the area marked green.

The inner diameter of the wheel is 8 cm, and I have a depth of about 4-5 cm to work in. Note however, that I didn't model how the wheel connects to the rest of the car, so the design should fit into the mid-left and upper-left sections of the space inside the wheel (the other parts are blocked).

What would be the best brake construction in this situation? The braking force should be as adjustable as possible. I've thought about possible mechanical constructions, like fastening a small micro servo motor to the stationary part, and using a rack & pinion to push a rubber brake into the inner side of the wheel. Another idea was to use the motor to rotate the piece below, and press either of the two rubber cylinders against the wheel, depending on which direction it was rotating in. (This however, seems prone to breaking if you press the wrong side into the rotating wheel...)

Am I starting off in the right direction, are there any better constructions I should've thought of or I should look into? Any help is greatly appreciated.

-Tusike