Bern123

- 16

- 0

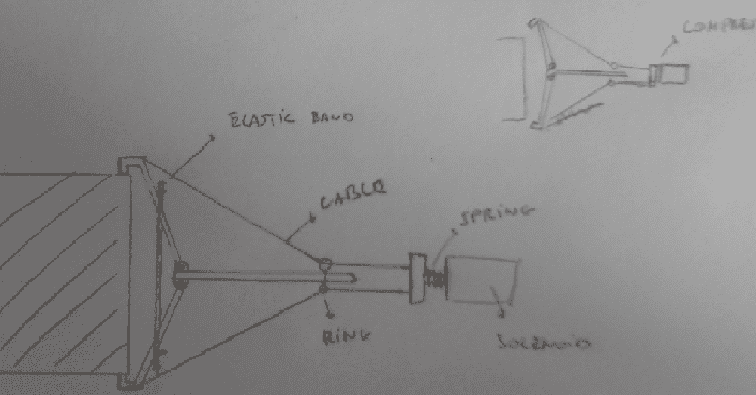

Hi all, i need to create an electric gripper, the speed of the greep need to be about 2ms. So i tought to use a solenoid that can be real fast, but i found only hydraulic solenoid(and i can't find force that they can generate in datasheets) or big and heavy solenoids(too much for my project). The greep don't need to be real strong but i really need to contain the price. The displacement of the gripper need to be at least 1cm per part(so the solenoid need to do a minimum 1cm movement). Any ideas? about a better gripper or where to find parts(the name of parts)?

I will really appreciate any help!

I tought something like this: (sorry for bad drawings)

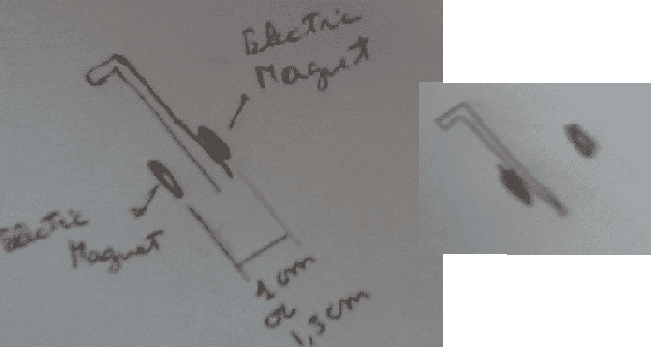

or

I will really appreciate any help!

I tought something like this: (sorry for bad drawings)

or