Travis T

- 18

- 2

- TL;DR

- Would like to calculate force required for a wedge cam design

Hi all,

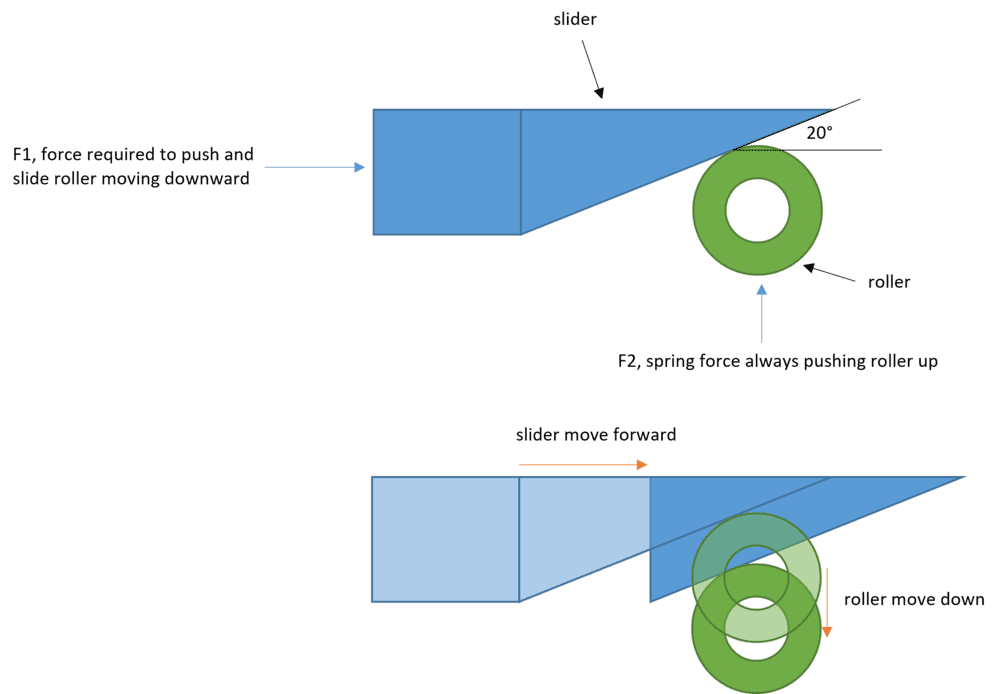

I'm currently designing a linear to linear transform mechanism (wedge cam design).

Would like to check how much force required to push/ slide the roller down.

To ease calculation, i have include some assumption:

F2 = 1kg @ maximum compressed

angle = 20degree

F1 required = ?

and how to draw the resultant force diagram for this example?

Thanks.

I'm currently designing a linear to linear transform mechanism (wedge cam design).

Would like to check how much force required to push/ slide the roller down.

To ease calculation, i have include some assumption:

F2 = 1kg @ maximum compressed

angle = 20degree

F1 required = ?

and how to draw the resultant force diagram for this example?

Thanks.