Ian C

- 1

- 0

Hello - I've been trying to solve this for a little while, and feel I may not understand some core concepts required to solve the problem. If you have any ideas, please let me know! I would very much like to discuss how to solve this.

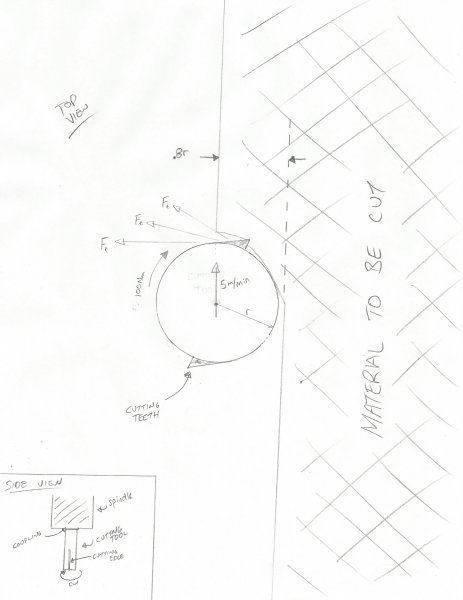

I am trying to calculate the bend moment from a rotating cutting tool as it moves through the material it is cutting. As the tool rotates, it moves into the material radially in the XY plane (as to say the cutting action is not plunging in Z).

The cutting tool is coupled/attached to the machine spindle. This coupling is rated for a specific force, or radial load applied to the cutting tool as it cuts before the coupling is compromised (in this case, let's say 500Nm).

My thinking is this (please see attached image):

As each 'tooth' of the cutting tool shears the material, a specific torque is required (lets call it T, and say T=100Nm). The tool is moving forward, into the material at a speed of 5m/min, turning at an RPM where the teeth of the tool continually take the same depths of cut requiring the same 100Nm of torque to shear/cut the material.

To me, this means that there is an opposite tangential force at the peripheral edge of each cutting edge.

This thinking sort of breaks down though as the force exerted tangentially on the circumference of the tool is changing direction as the cutting edge rotates, as well as the entire tool being fed into the material.

So that's the problem - I totally understand if its not clear, but I'm happy to clarify points and discuss.

Ian.

I am trying to calculate the bend moment from a rotating cutting tool as it moves through the material it is cutting. As the tool rotates, it moves into the material radially in the XY plane (as to say the cutting action is not plunging in Z).

The cutting tool is coupled/attached to the machine spindle. This coupling is rated for a specific force, or radial load applied to the cutting tool as it cuts before the coupling is compromised (in this case, let's say 500Nm).

My thinking is this (please see attached image):

As each 'tooth' of the cutting tool shears the material, a specific torque is required (lets call it T, and say T=100Nm). The tool is moving forward, into the material at a speed of 5m/min, turning at an RPM where the teeth of the tool continually take the same depths of cut requiring the same 100Nm of torque to shear/cut the material.

To me, this means that there is an opposite tangential force at the peripheral edge of each cutting edge.

This thinking sort of breaks down though as the force exerted tangentially on the circumference of the tool is changing direction as the cutting edge rotates, as well as the entire tool being fed into the material.

So that's the problem - I totally understand if its not clear, but I'm happy to clarify points and discuss.

Ian.